Managing the Health of Fire Resistant Steam Turbine Electrohydraulic (EHC) Control Oils

Tags: turbine lubrication

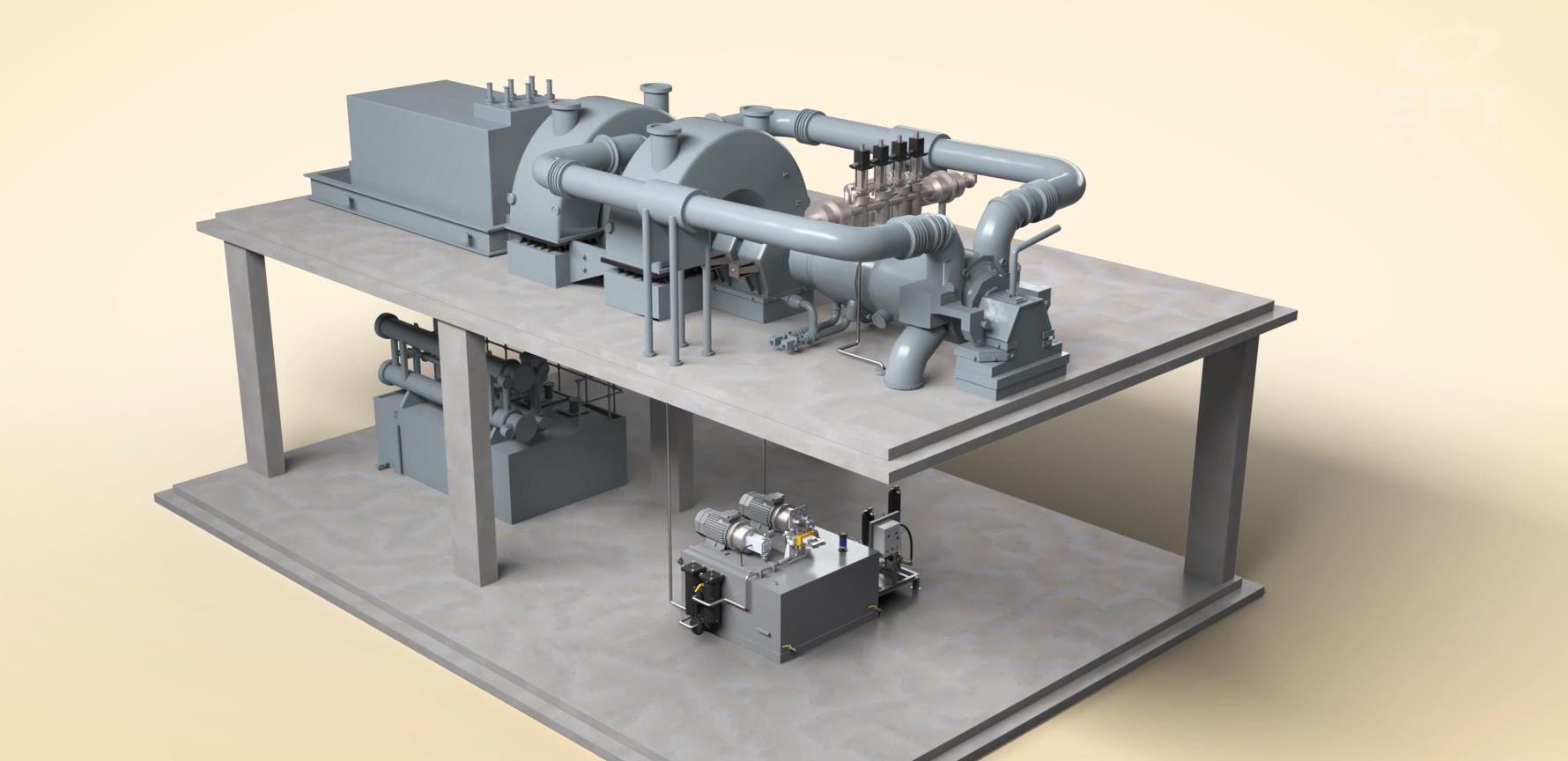

The importance of fluid health is never more apparent than on an electrohydraulic control (EHC) system that is responsible for the critical task of governing steam delivery to turbines that drive electric generators in a power plant. Historically, these systems employed mineral oil-based fluids. However, increasing steam temperatures (500°C to 550°C) and hydraulic fluid pressures (1,500 psi or 10 bar) demand the use of fire-resistant fluids to assure safe and reliable operation.

Phosphate ester-based hydraulic fluids are easily the most common fire-resistant EHC fluids in use today. Phosphate ester fluids offer higher flash and fire points than mineral oils, and most importantly, they self-extinguish and are less likely to spread flaming streams or burning pools of oil. These properties serve to protect personnel, the fixed assets and the public.

Generally speaking, esters are the result of a chemical reaction between an organic or inorganic acid with an alcohol or other organic compound containing the hydroxyl radical. Specifically, phosphate esters can be called organic salts of orthophosphoric acid. While there are thousands of organo-phosphorous compounds, only a few are useful as base oils for fire-resistant fluids. Table 1 summarizes commonly used phosphate ester fluids.

|

Triaryl Phosphate Ester Fluids

|

||||

|

||||

| TXP | Trixylenyl Phosphate Ester |

• Best air release characteristics • Best hydrolytic stability • Good overall |

||

| TBPP | Butylated Phenol Phosphate Ester | Best bulk oxidation resistance | ||

| IPPP | Isopropyl Phenol Phosphate Ester | Better hydrolytic stability than butylated synthetics | ||

| TXP and TBPP |

Blend of Butylated Phenol and Trixylenyl Phosphate Ester |

Properties vary from batch to batch | ||

|

Table 1. Several phosphate ester fluid options exist, including blends.

Each offers its own specific features and benefits. |

||||

Phosphate ester-based fire-resistant fluids were originally introduced in the 1950s in response to fires caused by the spray of hydraulic fluid from ruptured lines onto hot surfaces. They have provided more than 50 years of reliable service to the power generation industry. They are also widely used in steel mills and foundries, natural gas compressors and aircraft hydraulic control systems. The reliability of phosphate esters depends upon the quality of maintenance.

They deliver excellent performance when properly maintained. Corrosion, valve sticking and unsatisfactory system performance can be expected when phosphate esters are deprived of proper fluid maintenance.

Steam turbine electro-hydraulic control (EHC) system failures, including sticking or eroded servo valves, and plugged filters and strainers, can be avoided through active management of phosphate ester control fluid quality. Proactively manage your oil’s chemistry with contamination-removal solutions that comply with the requirements outlined in ASTM D8323. EPT Clean Oil’s proven solutions, including ICB™ FRF, ECR™ Combo and TMR™ N2, have saved steam turbine-users hundreds of thousands of dollars in fluid replacement and system flushing costs while eliminating common EHC failure pathways.

What’s In a Change?

Phosphate ester fluids should provide years of trouble-free service. Many power generation stations have exceeded 20 years of service without performing a drain or partial drain and enjoyed reliable system performance. Others, however, find themselves changing the fluid at every outage cycle and still suffer rapid fluid degradation (characterized by acid build up and sludging), sticking valves, eroded servovalves, plugged filters and/or blocked servovalve strainers.

The difference in the two scenarios comes down to maintenance; often simple, easy-to-correct practices. The failure to effectively maintain these systems can’t be completely attributed to operators. Often, documentation from turbine suppliers is incomplete, out-of-date and/or contradictory in its advice.

New phosphate ester hydraulic fluid is expensive, costing $20 to $30 per gallon depending upon the fluid type and supplier. But fluid cost is just the tip of the iceberg. First and foremost, the oil change itself can introduce problems in the system if not properly planned and carried out. Following is a summary of the costs associated with a fluid change-out:

1. Purchase of new fluid ($20 to $30 per gallon)

2. Outage time (up to 14 days or more)

3. Labor costs

4. Disposal of used fluid, including drums, storage, testing, shipping and paperwork

5. Flush fluid, if required

6. Flush fluid disposal

7. Unplanned risk-based costs for delays, spills and leaks, compatibility problems, contamination, dry starts, etc.

The price for the fluid alone can total $30,000 to $50,000, and can occupy a crew for weeks. The total price for making the change can add up to multiples of that figure. Fortunately, replacing a fluid usually coincides with an outage. If not, the price can reach into the millions. Sticking control valves and changing servovalves, or having to derate the unit to change a filter element can also be costly.

Therefore, it is a wise investment to keep the fluid in good condition. Fluid changes and equipment add-ons can mask the root cause. If the root cause is not corrected, the problems tend to reappear in three to five years. Power stations that cannot keep up with basic maintenance will face greater problems with any new equipment added to their

workload.

Maintaining Phosphate Ester Fluids

Although it is an easy procedure, fluid maintenance is often overlooked. For example, one turbine manufacturer requires changing the pump discharge filters twice a year and the purification media four times a year. This consumable cost is only $3,000 but it is a procedure often disregarded. Such simple maintenance is necessary because these fluids degrade somewhat during typical service.

The fluid is pressurized, subjected to elevated temperatures, flows through fine clearances and is exposed to contaminants including water, dirt and air. With most systems, the originally supplied filtration and purification equipment and the composition of the new fluid will offset normal degradation. This should extend fluid life to 15 years or longer. Although original purification equipment is usually adequate, upgrades such as automatic air vents for housings, flow gauges, proper pressure gauges and better filter elements to fit in existing housings are simple, cost-effective add-ons.

Most fluid-related problems can be traced to contamination by an incompatible material or inadequate fluid purification for one or more of the following reasons:

1. Purification media are not changed often enough.

2. Flow rate through the purification media is too low, too high or not at all.

3. The purification media is too wet, even when new.

4. Purification housings are air bound and require better venting.

5. Housing, system bypass or pressure relief valves are defective.

6. The wrong purification media are used.

7. The wrong fluid is used.

8. Fluid is overstressed because of heaters, running both pumps, missing thermal insulation, etc.

9. Fluid is contaminated with an incompatible fluid, sealant or other chemical.

Fluid maintenance is simple: Keep it dry, clean and purified. Pay attention to material compatibility issues and employ regular fluid condition monitoring.

Keep it Clean, Dry and Purified

Effective purification is critical to effective fluid performance and system reliability. Problems with purification systems can result in rising acid number, falling resistivity and/or excessive particle count.

Ironically, phosphate ester fluid is very hygroscopic (attracts water) but has poor hydrolytic stability (the fluid degrades in the presence of water). Some of the consequences of poor fluid purification practices include shortened fluid life, corrosion, increased maintenance, plugged filters, blocked servovalve strainers, electrokinetic wear of spools, and sticking servovalves and solenoid valves - all of which can be prevented by properly purifying the fluid.

Phosphate ester purification may include the following different separation technologies:

-

Mechanical particulate removing filters - usually Beta-Two > 75 quality elements to protect the servovalve from sticking.

-

Water control - vacuum distillation removes dissolved water whereas centrifugal separators do not work because of phosphate ester’s great affinity for water.

-

Acid scrubbing by adsorptive media - fuller’s earth, activated alumina, etc., are used to strip acids out of the fluid.

GE recommends (Reference GEK-46355E - Hydraulic Power Unit) changing fuller’s earth filter elements when:

-

The pressure differential across the filter reaches 30 psi (207 kPa), or every three months, whichever comes first, or

-

The chlorine content of the fluid is >150 ppm, or

-

The H2O content of the fluid is >0.20%, or

-

The acid number reaches 0.20 mg/kg KOH. This value was lowered in EHC Fluid Specifications, GEK 46357A, page 4, January 1979. Current version is revision E.

NOTE: Always change all filter elements at the same time.

GE recommends changing media every three months. However, stations with media in service for 15 years or more have been changing-out media at six-month intervals. However, this requires never missing or delaying a media change-out so that the acid number rises.

Achieving consistently low particle counts requires filters to be adequately maintained - both on time and on pressure drops. New filters with inorganic media tend to have higher beta ratios and should be more effective at removing smaller particles.

Consider these additional measures in the maintenance of phosphate ester fluids:

- Stay within OEM limits, changing filters every six months.

- Save and evaluate used purification media cartridges.

- Save and evaluate filter elements and screens.

- Trend filter and purification media differential pressures.

- Record fluid make-up (date, volume and circumstances).

- Use machine tags to note filter and media change details.

Portable purification systems can be helpful in the short-term to solve specific problems. Add-on purification systems and media can also be beneficial, but they cannot correct all problems. They may even create new difficulties if the fluid is pushed beyond its capabilities.

To correctly perform fluid maintenance, operators and mechanics must understand phosphate ester fluids and their unique tendencies and requirements. These individuals must clearly understand what constitutes fluid maintenance best practice and have clear, written procedures on their deployment.

They should be trained to recognize abnormal fluid and system conditions. They should also be encouraged to question the suitability of a new part that appears different.

Material Compatibility

While triaryl phosphate esters can have the same viscosities as mineral oils, the material requirements can be quite different. Material incompatibility issues are well documented, but infractions can plague even larger power stations having many staff members. Following are some examples of compatibility issues:

-

Ethylene-propylene (EPR) and butyl rubbers are suitable for phosphate esters but not for mineral oil.

-

Nitrile rubber (Buna-N) is commonly used for mineral oil, but should not be used with any phosphate esters.

-

Phosphate ester fluids are often used as plasticizers with polyvinyl chloride (PVC) materials to soften and lend flexibility. Consequently, PVC machine components and coated wires can be softened if left in contact with these fluids.

-

Phosphate ester will soften standard paints so that epoxy-based paints are required. Leather, cellulose (paper) and the fluorocarbon elastomers are typically compatible.

One method for evaluating compatibility involves immersing a sample of the material in the fluid and soaking it at an elevated temperature. One simple test suggested by GE is to immerse a sample of the material in question in fluid that is maintained at 140°F (60°C) for seven days. Up to five percent shrinkage or 15 percent swelling is deemed acceptable, so even approved materials may be affected to some extent.

One method for evaluating compatibility involves immersing a sample of the material in the fluid and soaking it at an elevated temperature. One simple test suggested by GE is to immerse a sample of the material in question in fluid that is maintained at 140°F (60°C) for seven days. Up to five percent shrinkage or 15 percent swelling is deemed acceptable, so even approved materials may be affected to some extent.

In addition, elastomer compounds in the same family (or even from different suppliers) can vary widely. If in doubt, contact the component supplier for specific recommendations.

The suitability of a particular compound depends on the material and the application. In one application some swell may be acceptable, while in others it may not be. It is generally acceptable with static captured seals (grooved O-rings) but not with parts where there is motion.

Silicone-based rubber and/or sealants may be unsuitable for contact with EHC fluids but are reportedly acceptable as a coating for wires. This is not because of softening.

There have been reports of adverse effects on the air release time of fluid-entrained air bubbles. In susceptible systems, it can lead to more rapid fluid degradation because of excessive air being pulled into the circulating pressurized system.

There can be considerable differences between the recommendations from component suppliers. If in doubt, contact the fluid supplier or perform specific tests to determine the compatibility of the material in question. A field test for an O-ring is to drop it into a container of the fluid (SG of 1.13). If it sinks, the O-ring is likely Viton (SG of 1.85) and is acceptable.

A floating O-ring, on the other hand, indicates two possible outcomes: It might be Buna-N (SG of 1.0), which is not OK; or it could be butyl rubber (SG of 0.92), which is acceptable for lower temperature applications.

| 7 Easy Steps for Fluid Care and Feeding Steam Turbine Control Systems | |

|

1. Assign one person or one team to be responsible for/or available as a resource for most aspects of operation and maintenance. Ensure that there is adequate experience and/or recent training. If not, contact suppliers for assistance and provide needed training. For example, GE has an annual meeting for users. Most other suppliers also offer seminars.

2. Keep up-to-date material available. This includes OEM technical data and specification materials from the suppliers for the turbine, fluid, filters and purification media. 3. Follow the turbine manufacturers’ recommendations for maintenance. If your maintenance procedure differs, justify it with detailed technical records. Check assumptions at least once a year. The justification should take into consideration the consequences of not following manufacturers’ recommendations. For example:

|

4. Benchmark the actual versus recommended maintenance at least once per year. Reviewing work reports and store withdrawals is often helpful. The store withdrawals can be particularly useful to ensure the work is completed as required. It can also check on what has been ordered and/or delivered. Do not use substitute materials unless proven to be technically better. 5. Ensure maintenance procedures are correct. Help new staff or staff doing a job for the first time to do it correctly. Many common tasks such as trap filter changes are neither simple nor obvious. In fact, it is easier to do them wrong than right. Fortunately, maintainability can be improved at very little cost with air release valves and/or better filters. 6. Be proactive and if in doubt, ask. At least once per week, check system status including pressure drops across all filters and purification media, fluid temperature and fluid level. Sample the fluid at least bimonthly and send it to the fluid supplier for testing. Proper sampling is essential, and usually there is no charge for such testing. Trend plotting can be very helpful. For the fluid, try to stay well within the OEM limits. 7. Walk the system and lines once a week. Check machine performance, looking for drips, missing heat shields, fretting lines, loose pipe hangers or anything that will cause problems. During the walk-down, note pressure and temperature readings to be used for trending. |

Not all compounds are the same because seal suppliers can have different blends. There are versions of the same family such as Viton A, B and GF. The temperature of the application is also important; the higher the temperature, the greater the effects.

There can be variations in the performance of materials from different seal manufacturers supplying the same material type by the same trade name. Specific tests may be required for critical applications or for problems with swelling or disintegration. Refer to ASTM D471 for elastomer-fluid compatibility test methods.

CAUTION: If in doubt, call the fluid supplier. Not all the elastomer suppliers’ data is appropriate for use with these fluids in control systems.

Fluid Condition Monitoring

To reduce the negative impact of fluid degradation, a condition-monitoring program must be strictly followed. The goal is to reduce operational problems and damage to equipment that results from uncontrolled fluid degradation. An essential element in achieving this goal is the performance of fluid analysis by a suitable laboratory.

Monitoring the fluid also includes frequent testing and trending of selected physical-chemical characteristics to detect changes that might cause operational problems. Try to catch small problems before they become big problems.

The five leading suppliers of turbine oil have 27 different tests for new fluid and for new fluid deliveries. On the other hand, they have very few tests for condition monitoring. The fluid suppliers perform different tests as part of their routine quality control testing. Some stations contract their testing out to commercial labs. If they use an in-house lab, there is the chance the lab does not have adequate experience with phosphate esters.

Resistivity is one test often left out, probably because of the difficulty in locating the instrument test cell. However, for high-pressure control systems with servovalves, this is an important measure. It is necessary to warn of potential electrokinetic wear.

An effective fluid condition-monitoring program is beneficial for the following reasons:

1. Fluid that is maintained in good chemical condition will last longer and will require less maintenance. Many of the fluid degradation by-products are autocatalytic. If allowed to accumulate, they will degrade the rest of the fluid. If left uncared for, this will worsen at an increasingly faster degradation rate.

2. Fluid with low acid numbers tends to require fewer purification media changes than fluid which breached the acceptable limits. Phosphate ester fluids with high acid numbers often cannot be successfully recovered with the OEM purification systems, especially if fuller’s earth is used.

3. Fluids and the system require less maintenance when clean. Contaminants and wear debris can accelerate fluid degradation. In addition, cleaner fluid should mean less maintenance on dirt sensitive system components such as pumps, filter elements, screens and servovalves.

4. Fluid that has always been in good condition is less likely to cause deposits on servo and solenoid valves. Filter element life can also be extended and the recommended periodic reservoir cleaning may not be necessary. Fluids have a history that can be repeated. Even if a fluid’s problem has been corrected, it can cause problems down the road.

5. Fluid analysis can warn of problems with pumps and valves before other signs are obvious. Corrective action can often be taken before significant damage occurs.

6. A comprehensive control fluid condition-monitoring program is specified by all turbine manufacturers and costs little. The two major suppliers of phosphate ester fluid provide routine analysis of phosphate ester control fluid at no charge. Sample bottles are provided as well.

Proper sampling is important, especially for particle counts. When performing fluid analysis:

- Sample fluid at the proper frequency.

- Take samples at the appropriate place.

- Follow correct sampling procedures.

- Use the test procedures.

- Use qualified staff and lab.

- Evaluate results and take appropriate corrective measures.

Phosphate ester fluid can give years of trouble-free service if proactive measures are taken to prevent problems. Effective maintenance of phosphate ester fluid is best accomplished by trained personnel who have experience with these fluids, and know how to perform a proper root cause analysis when problems arise. To achieve success with phosphate ester fluids, the user must diligently purify the fluid and utilize condition monitoring to collect data.

System maintenance of EHC systems is a challenging task, but done properly, it rewards the power station with improved availability and reduced system and fluid maintenance costs. Fortunately, help is available to those who look for it.