Base Oil Groups Explained

Tags: industrial lubricants

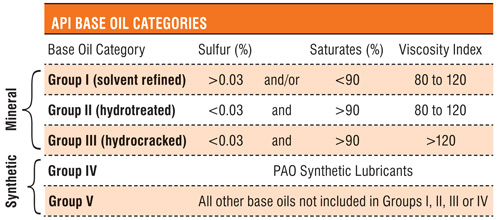

Almost every lubricant used in plants today started off as just a base oil. The base oil category defines what the oil is made of, how it is manufactured, and how the lubricant handles certain environments such as extreme heat.The American Petroleum Institute (API) has categorized base oils into five categories (API 1509, Appendix E). The first three groups are refined from petroleum crude oil.

Group IV base oils are full synthetic (polyalphaolefin) oils. Group V is for all other base oils not included in Groups I through IV. Before all the additives are added to the mixture, lubricating oils begin as one or more of these five API groups.

Group I

Group I base oils are classified as less than 90 percent saturates, greater than 0.03 percent sulfur and with a viscosity-index range of 80 to 120. The temperature range for these oils is from 32 to 150 degrees F. Group I base oils are solvent-refined, which is a simpler refining process. This is why they are the cheapest base oils on the market.

Group II

Group II base oils are defined as being more than 90 percent saturates, less than 0.03 percent sulfur and with a viscosity index of 80 to 120. They are often manufactured by hydrocracking, which is a more complex process than what is used for Group I base oils. Since all the hydrocarbon molecules of these oils are saturated,

Group II base oils have better antioxidation properties. They also have a clearer color and cost more in comparison to Group I base oils. Still, Group II base oils are becoming very common on the market today and are priced very close to Group I oils.

Group III

Group III base oils are greater than 90 percent saturates, less than 0.03 percent sulfur and have a viscosity index above 120. These oils are refined even more than Group II base oils and generally are severely hydrocracked (higher pressure and heat). This longer process is designed to achieve a purer base oil.

Although made from crude oil, Group III base oils are sometimes described as synthesized hydrocarbons. Like Group II base oils, these oils are also becoming more prevalent.

Group IV

Group IV base oils are polyalphaolefins (PAOs). These synthetic base oils are made through a process called synthesizing. They have a much broader temperature range and are great for use in extreme cold conditions and high heat applications.

| 57% | of lubrication professionals use both synthetic and mineral-based lubricants in their plant, according to a recent poll at machinerylubrication.com |

Group V

Group V base oils are classified as all other base oils, including silicone, phosphate ester, polyalkylene glycol (PAG), polyolester, biolubes, etc. These base oils are at times mixed with other base stocks to enhance the oil’s properties. An example would be a PAO-based compressor oil that is mixed with a polyolester.

Esters are common Group V base oils used in different lubricant formulations to improve the properties of the existing base oil. Ester oils can take more abuse at higher temperatures and will provide superior detergency compared to a PAO synthetic base oil, which in turn increases the hours of use.

API Base Oil Groups

In the early 1990s, the American Petroleum Institute implemented a system for describing various base oil types. The result was the development and introduction of base oil group numbers.

Group I base oils are the traditional older base oils created by a solvent-refining technology used to remove the weaker chemical structures or bad actors (ring structures, structures with double bonds) from the crude oil. Solvent refining was the primary technology used in refineries built between 1940 and 1980.

Group I base oils typically range from amber to golden brown in color due to the sulphur, nitrogen and ring structures remaining in the oil. They typically have a viscosity index (VI) from 90 to 105. The base oils on the high end of the scale are often referred to as having a high viscosity index (HVI).

This relates to how much the viscosity changes with temperature, i.e., how much it thins out at higher temperatures and thickens at low temperatures. Group I base oils are the most common type used for industrial oils, although increasingly more Group II base oils are being used.

Group II base oils are created by using a hydrotreating process to replace the traditional solvent-refining process. Hydrogen gas is used to remove undesirable components from the crude oil. This results in a clear and colorless base oil with very few sulphur, nitrogen or ring structures.

The VI is typically above 100. In recent years, the price has become very similar to Group I base oils. Group II base oils are still considered to be mineral oils. They are commonly used in automotive engine oil formulations.

Group II “Plus” is a term used for Group II base oils that have a slightly higher VI of approximately 115, although this may not be an officially recognized term by the API.

Group III base oils are again created by using a hydrogen gas process to clean up the crude oil, but this time the process is more severe and is operated at higher temperatures and pressures than used for Group II base oils. The resulting base oil is clear and colorless but also has a VI above 120. In addition, it is more resistant to oxidation than Group I oils.

The cost of Group III base oils is higher than Group I and II. Group III base oils are considered mineral oils by many technical people because they are derived directly from the refining of crude oil. However, they are considered synthetic base oils by other people for marketing purposes due to the belief that the harsher hydrogen process has created new chemical oil structures that were not present before the process. It has synthesized (created) these new hydrocarbon structures. See the section on synthetic base oils in this book.

Group I, II and III base oils basically reflect the evolution in refining technology over the past 70 or 80 years.

Group IV base oils are polyalphaolefin (PAO) synthetic base oils that have existed for more than 50 years. They are pure chemicals created in a chemical plant as opposed to being created by distillation and refining of crude oil (as the previous groups were).

PAOs fall into the category of synthetic hydrocarbons (SHCs). They have a VI of greater than 120 and are significantly more expensive than Group III base oils due to the high degree of processing needed to manufacture them.

Group V base oils comprise all base oils not included in Groups I, II, III or IV. Therefore, naphthenic base oils, various synthetic esters, polyalkylene glycols (PAGs), phosphate esters and others fall into this group.

Base Stock Physical Properties

These tests help describe key physical characteristics of new base oils:

| Property | Why It Is Important | How It Is Determined | ASTM No. |

|---|---|---|---|

| Viscosity | Defines base oil viscosity grade | Gravity flow capillary viscometer | D445 |

| Viscosity Index |

Defines viscosity-temperature relationship |

Viscosity variance between 40 degrees C and 100 degrees C, indexed |

D2270 |

| Specific Gravity |

Defines density of oil relative to water |

Hydrometer | D1298 |

| Flash Point |

Defines high-temp volatility and flammability properties |

Flash point tester, temp. at which flash surface flame is achieved |

D92/D93 |

| Pour Point |

Defines low-temp oil fluidity behavior |

Gravity flow in test jar, temp at which approximately 22,000 cSt is reached |

D97/IP15 |

The Changing Use of Base Oils

A recent study on the use of base oils in today’s plants in comparison to a little more than a decade ago found a dramatic change has occurred. Present-day Group II base oils are the most commonly used base oils in plants, making up 47 percent of the capacity of plants in which the study was conducted.

This compared to 21 percent for both Group II and III base oils just a decade ago. Currently, Group III accounts for less than 1 percent of the capacity in plants. Group I base oils previously made up 56 percent of the capacity, compared to 28 percent of the capacity in today’s plants.

Remember, whichever base oil you choose, just be sure it is appropriate for the application, temperature range and conditions in your plant.