How Desiccant Breathers Control Contamination

Tags: contamination control, preventive maintenance

To combat the ingression of particles into oil systems, breathers are commonly attached to reservoirs and other oil storage components. Whether connected to an expensive machine or a simple oil drum, breathers offer peace of mind. As oil levels fluctuate, breathers ensure that the incoming air is properly cleaned and mostly free of contaminants.

The Rise of Desiccant Breathers

Desiccant breathers are popular thanks to their ability to remove both solid particles and water vapor from incoming air. While they may look like a simple plastic cup filled with beads, these devices rely on powerful chemical and physical processes to protect critical lubrication systems.

Although breathers are simple to install, the chemistry and engineering behind them are sophisticated. By effectively controlling airborne moisture and particles, desiccant breathers protect critical components and help maintain the delicate fluid film that machinery depends on.

3 Key Properties of a Good Desiccant Breather

A high-performing desiccant breather system should:

-

Achieve Target Cleanliness and Dryness Levels - Prevent both water and particulate ingression effectively.

-

Provide Sufficient Service Life - Offer long intervals between required change-outs.

-

Allow for Easy Visual Inspection - Support preventive maintenance through clear, visible indicators.

Materials That Power the Process

Desiccant breathers use two of nature’s most absorbent materials:

-

Silica gel – The same material found in "Do Not Eat" packets in packaging.

-

Activated carbon – Known for its ability to attract and bond with various contaminants.

Step-by-Step Filtration Process

-

Initial Particle Filtration

At the top of the breather, a synthetic fiber filter captures large airborne particles like dust and organic debris. -

Airflow Diffusion

Next, a diffuser evenly distributes incoming air through the silica gel beads. -

Moisture Removal

As air passes through the silica gel, water vapor is trapped in its porous structure—silica can absorb up to 40% of its weight in water. -

Gas and Vapor Absorption

Any remaining moisture passes into a layer of activated carbon.-

Carbon’s high electronegativity attracts oxygen, forming new compounds (like CO₂).

-

Water vapor’s oxygen binds with carbon, preventing it from contaminating the lubricant.

-

-

Exhalation Process (Reverse Flow)

When the system exhales, air flows in reverse.-

The activated carbon absorbs any oil mist, ensuring that contaminated vapors don’t re-enter the lubricant.

-

Features That Improve Usability and Performance

Desiccant breathers offer more than just basic filtration—they are designed with several features that enhance performance, extend service life, and make maintenance easier.

Color-Change Indicator for Moisture Saturation

Many desiccant breathers come equipped with a color-change indicator. This feature uses a water-reactive reagent embedded in the silica beads that changes color as moisture is absorbed. The color shift provides a clear, visual cue that the breather has reached the end of its useful life and needs to be replaced.

Vacuum Gauge for Filter Monitoring

In some operating environments—particularly dry or dusty ones—moisture levels may be too low to activate the silica's color change before the particulate filter becomes clogged. In these cases, a vacuum gauge is recommended. It gives a visual signal of rising pressure as the filter clogs, alerting operators to restricted airflow and the need for replacement.

Modular Add-Ons for Enhanced Performance

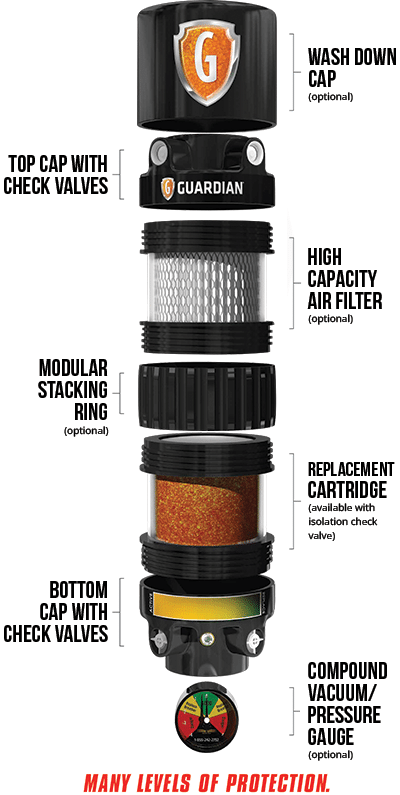

Advanced desiccant breathers such as the Guardian® series offer modular add-ons that further improve system reliability and adaptability for a range of operating conditions:

-

Shield Wash Down Cap

Protects the breather during equipment washdowns or in environments where direct water spray is common. -

High-Capacity Air Filter

Offers enhanced particle filtration in dusty or heavily contaminated environments, increasing the lifespan of the breather. -

Modular Stackable Ring™

Allows for easy expansion of desiccant capacity to extend service intervals in high-humidity environments. -

Isolation Check Valve

Prevents the backflow of air or oil mist, ensuring contaminants do not return into the system during pressure reversals. -

Compound Indicating Gauge

Combines pressure and vacuum indication into one unit, allowing operators to monitor system conditions at a glance and make timely maintenance decisions.

These add-ons make the system highly customizable, allowing users to tailor breather performance to specific equipment, environmental conditions, and maintenance strategies.

Considerations for Breather Selection

Choosing the right desiccant breather for your application involves more than simply picking one off the shelf. A breather’s effectiveness depends on a variety of operational and environmental factors. To ensure optimal protection for your equipment and maximize breather life, it's important to evaluate the specific conditions your system will encounter.

Here are the key factors to keep in mind:

Environmental Conditions

-

Cleanliness of the Surrounding Air: The dirtier the environment, the more contaminants the breather will trap—and the faster it will reach its capacity. In dusty settings, consider a breather with a high-capacity air filter or modular expansion options.

-

Humidity Levels: Higher ambient humidity leads to quicker saturation of the silica gel. In these environments, using a larger desiccant volume or modular stackable rings can help extend service life.

Machinery Criticality

-

Equipment Sensitivity: The criticality of the equipment the breather is protecting should influence your selection. High-precision machinery with tight tolerances will require more robust, high-efficiency filtration solutions and shorter change-out intervals to prevent damage from particle or moisture ingress.

Installation Best Practices

To ensure maximum efficiency:

-

Tightly seal the oil reservoir’s headspace.

-

Ensure that the only air entering the system passes through the breather.

-

Avoid loose seals, which can allow unfiltered air to bypass the breather.