The Hidden Dangers of Lubricant Starvation

Tags: industrial lubricants

For those who strive for lubrication-enabled reliability (LER), more than 95 percent of the opportunity comes from paying close attention to the “Big Four.” These are critical attributes to the optimum reference state (ORS) needed to achieve lubrication excellence. The “Big Four” individually and collectively influence the state of lubrication, and are largely controllable by machinery maintainers. They are well-known but frequently not well-achieved. The “Big Four” are:

- Correct lubricant selection

- Stabilized lubricant health

- Contamination control

- Adequate and sustained lubricant level/supply

The first three of the “Big Four” have benefited from considerable industry attention, especially in recent years. Conversely, the last one has gone relatively unnoticed yet is no less important. Therefore, it will be the central focus of this article.

Over the past few decades, researchers and tribologists have compiled countless listings that rank the chief causes of machine failure. We’ve published many of these in Machinery Lubrication magazine. The lists ascribe the causes of abnormal machine wear to the usual suspects: contamination, overheating, misalignment, installation error, etc. There’s typically a lubrication root-cause category that is a catch-all for one or more causes that can’t be easily specified or named. I’ve seen terms used like “inadequate lubrication” and “wrong lubrication.”

Understandably, it is difficult for failure investigators and analysts to trace back the exact sequence of events beginning with one or more root causes. Evidence of these causes is often destroyed in the course of failure or in a cover-up during the cleanup and repair. Having led several hundred such investigations over the years, I’ve learned that one root cause in particular is too often overlooked - lubricant starvation.

| 81% | of lubrication professionals have seen the effects of lubricant starvation in the machines at their plant, according to a recent survey at machinerylubrication.com |

Although most everyone knows about this in principle and realizes the common sense of adequate lubricant supply, it is frequently ignored because many typical forms of lubricant starvation are largely hidden from view.

For instance, who notices the quasi-dry friction that accelerates wear each time you start an automobile engine? This is a form of lubricant starvation. It’s not a sudden-death failure, but it is a precipitous wear event nonetheless. Each time controllable wear goes uncontrolled, an opportunity is lost to prolong service life and increase reliability.

The Nature of Lubricant Starvation

Machines don’t just need some lubricant or any lubricant. Rather, they need a sustained and adequate supply of the right lubricant. Adequate doesn’t just mean dampness or the nearby presence of lubricant. What’s defined as adequate varies somewhat from machine to machine but is critical nonetheless.

High-speed equipment running at full hydrodynamic film has the greatest lubricant appetite and is also the most punished when starved. Machines running at low speeds and loads are more forgiving when lube supply is restricted. Even these machines can fail suddenly when severe starvation occurs.

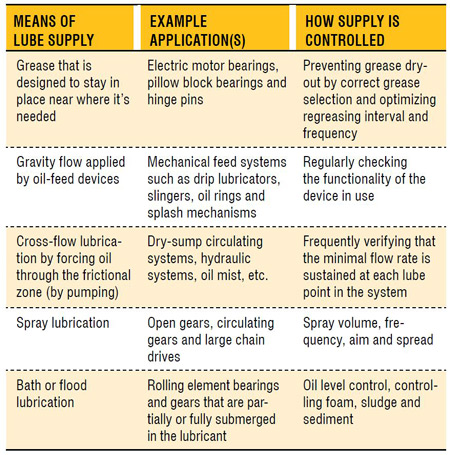

The table below illustrates how lubricants reach frictional surfaces in numerous ways.

There are six primary functions of a lubricating oil. These are friction control, wear control, temperature control, corrosion control, contamination control and transmittance of force and motion (hydraulics). Each of these functions is adversely influenced by starvation conditions.

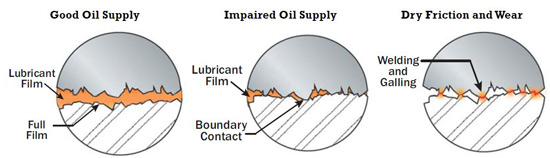

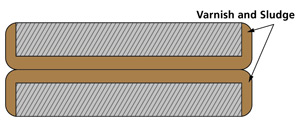

The worst would be friction, wear and temperature control. Even partial starvation intensifies the formation of frictional heat. It also slows the transport of that heat out of the zone. This is a compounding, self-propagating condition that results in collapsed oil films, galling, adhesive wear and abrasion (Figure 1).

Figure 1. Starvation Illustrated

In the case of grease, starvation-induced heating (from friction) of the load zone accelerates grease dry-out, which escalates starvation further. Heat rapidly drains oil out of the grease thickener, causing volatilization and base oil oxidation, all of which contributes to hardening and greater starvation.

Lubricating oil needs reinforcement, which is lost when flow becomes restricted or static. Flow brings in bulk viscosity for hydrodynamic lift. In fact, lack of adequate lubricant supply is functionally equivalent to inadequate viscosity from the standpoint of film strength.

4 Keys to Solving Starvation Problems Using Proactive Maintenance

- Identify the required lube supply or level to optimize reliability.

- Establish and deploy a means to sustain the optimized supply or level.

- Establish a monitoring program to verify the optimized supply or level is consistently achieved.

- Rapidly remedy non-compliant lube supply or level problems.

Oil flow also refreshes critical additives to the working surfaces. This reserve additive supply includes anti-wear additives, friction modifiers, corrosion inhibitors and others. Lubricant starvation produces elevated heat, which rapidly depletes additives.

Next, we know that wear particles are also self-propagating. Particles make more wear particles by three-body abrasion, surface fatigue and so on. Impaired oil flow inhibits the purging of these particles from the frictional zones. The result is an accelerated wear condition.

Finally, moving oil serves as a heat exchanger by displacing localized heat generated in load zones outward to the walls of the machine, oil reservoir or cooler. The amount of heat transfer is a function of the flow rate. Starvation impairs flow and heat transfer. This puts increasing thermal stress on the oil and the machine.

Common Signs of Starvation

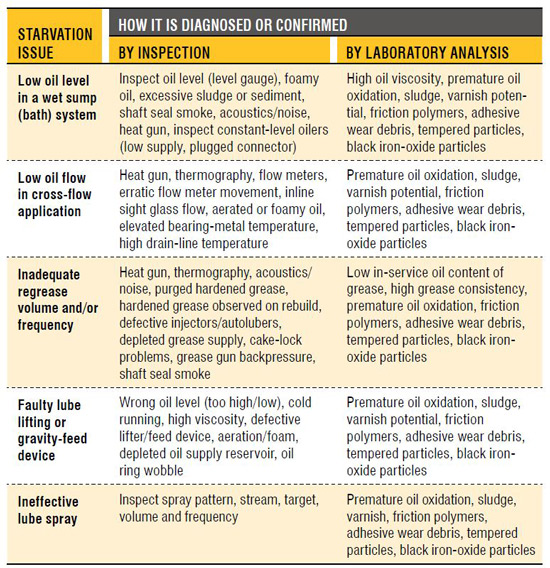

When you’re encountering chronic machine reliability problems, think through the “Big Four” and don’t forget about No. 4. It may not be the type of oil, the age of the oil or even the contamination in the oil, but rather the quantity of oil. How can you know? The chart on page 8 reveals some common signs of lubricant starvation.

Lubricant Starvation Examples by Machine Type

Lubricant starvation can happen in a number of ways. Most are controllable, but a few are not. The following abbreviated list identifies how lubricant starvation occurs in common machines.

Starved Engines

-

Dry Starts - Oil drains out down to the oil pan when the engine is turned off. On restart, frictional zones (turbo bearings, shaft bearings, valve deck, etc.) are momentarily starved of lubrication (Figure 2).

Figure 2. Dry Engine Starts - Cold Starts - Cold wintertime conditions slow the movement of oil in the engine during start-up. This can induce air in the flow line due to cold-temperature suction-line conditions.

- Low Oil Pressure - This can result from numerous causes, including worn bearings, pump wear, sludge and extreme cold. Oil pressure is the motive force that sends oil to the zones requiring lubrication.

-

Dribbling Injectors - Fuel injector problems can wash oil off cylinder walls and impair lubrication between the piston/rings and the cylinder wall.

Common Signs of Lubricant Starvation - Clogged Spray Nozzles and Orifices - Nozzles and orifices direct oil sprays to cylinder walls, valves and other moving components. Sludge and contaminants are able to restrict oil flow.

Starved Journal and Tilting-Pad Thrust Bearings

- Oil Groove Problems - Grooves and ports channel oil to the bearing load zones. Grooves become clogged with debris or sludge, restricting oil flow.

- Restricted Oil Supply - Pumping and oil-lifting devices can become mechanically faulty. This also may be due to low oil levels, high viscosity, aeration/foam and cold temperatures.

- Sludge Dam on Bearing Leading Edge - Sludge can build up on the bearing’s leading edge and restrict the oil supply.

Wet-Sump Bearing and Gearbox Starvation

-

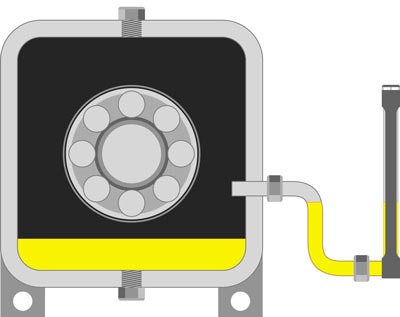

Oil Level - Many wet-sump applications require critical control of the oil level (Figure 3).

Figure 3. Common Splash Gear Drive - High Viscosity - Many oil-feed mechanisms (oil rings, slingers, splash feeders, etc.) are hampered by viscosity that is too high (wrong oil, cold oil, etc.). Gears can channel through thick, cold oil, interfering with splash and other feed devices.

-

Aeration and Foam - Air contamination dampens oil movement and impairs the performance of oil-feed devices (Figure 4).

Figure 4. How Aeration Retards Oil Supply - Non-horizontal Shafts - This can cause drag on oil rings and may interfere with slinger/flinger feed mechanisms.

- Bottom Sediment and Water (BS&W) - Sump BS&W displaces the oil level. On vertical shafts, the bottom bearing can become completely submerged in BS&W.

-

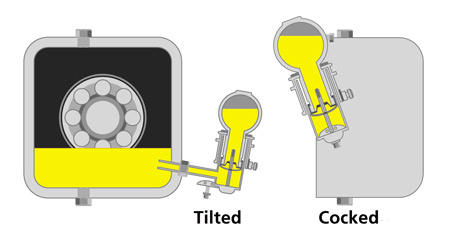

Defective Constant-Level Oilers - This may be due to plugged connecting pipe nipples, mounting errors (tilted, cocked, mounted on wrong side, etc.), wrong level setting, empty reservoir, etc. (Figure 5).

Figure 5. Mounting Errors of Constant-Level Oilers - Defective Level Gauge Markings - Level gauges should be accurately calibrated to the correct oil level.

-

Level Gauge Mounting and Viewing Issues - These may be hard to see, goosenecks, fouled gauge glass, gauge vent problems, etc. (Figure 6).

Figure 6. What is wrong with this picture?

Starved Dry-Sump Circulating Systems

- Restricted Oil Returns - Plugged or partially plugged oil returns will redirect oil flow away from the bearing or gearbox being lubricated. Sometimes called drip-and-burn lubrication, the condition is usually caused by sludge buildup or air-lock conditions in the gravity drain lines returning to the tank.

- Worn Oil Pump - When oil pumps wear, they lose volumetric efficiency (flow decay results).

- Restricted Pump Suction Line - Strainers and pickup tubes can become plugged or restricted. This can aerate the fluid, cause cavitation and lead to loss of prime.

-

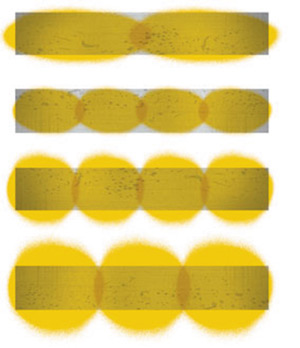

Clogged/Restricted Oil Ways and Nozzles - Oil-feed restrictions due to sludge, varnish and jammed particles can starve bearings and gears (Figure 7).

Figure 7. Plugged Oil Flow - Entrained Air and Foam - Oil pumps and flow meters perform poorly (or not at all) when sumps become contaminated with air (Figure 4).

- Lack of Flow Measurement - Components sensitive to oil supply require constant oil flow measurement.

- Defective or Miscalibrated Flow Meters - Flow meters, depending on the type and application, can present a range of problems regarding calibration.

- Low Oil Pressure - Oil follows the path of least resistance. Line breaks and open returns starve oil from higher resistance flow paths and the machine components they serve.

Starved Spray-Lubed Chains and Open Gears

- Defective Auto-lube Settings - This relates to correctly setting the lube volume and frequency.

-

Defective Spray Targets/Pattern - The oil spray needs to fully wet the target location. Spray nozzles can lose aim and become clogged (Figure 8).

Figure 8. Correct Lubricant Spray Patterns

on Open-Gear Tooth Flanks - Gummed Chain Joints - Many chains become heavily gummed, which prevents oil from penetrating the pin/bushing interface.

Starvation from Grease Single- and Multi-Point Auto Lubrication

- Wrong Regrease Settings - Regreasing settings should enable adequate grease replenishment at each lube point.

-

Cake-Lock - This occurs when grease is being pumped. Under certain conditions, the grease thickener movement is restricted. Oil flows, but the thickener is log-jammed in a line or component passage (Figure 9).

Figure 9. Cake-Lock

Grease Starvation - Defective Injector Flow - This is due to wrong injector settings or restricted injector displacement.

- Restricted Line Flow - Exceedingly long lines, narrow lines, numerous bends, ambient heat or cold, etc., can lead to partial or complete blockage of grease flow.

- Single-point Lubricator Issues - These include malfunctioning lubricators from various causes.

Starvation from Manual Lubrication Issues

- Grease Gun Lubrication - This may include an inaccurate volume calibration, a faulty grease gun mechanism, the wrong relube frequency, an incorrect relube volume or an improper relube procedure.

- Manual Oil Lubrication - This would include the wrong relube frequency, volume or procedure.

- Lube Preventive Maintenance (PM) - Missed PMs may be due to scheduling, management or maintenance culture issues.

The Crux of the Problem

Lubricant starvation is an almost silent destroyer. While there are telltale signs, they generally aren’t recognized or understood. Of course, there are varying degrees of starvation. Complete starvation is sudden and blatant. However, more moderate partial starvation is what tends to go unnoticed until failure. Then, other suspect causes (the bearing, lubricant, operator, etc.) may be falsely blamed.

Precision lubrication supply is a fundamental attribute of the optimum reference state and is included in any engineering specification for lubrication excellence. It’s one of the “Big Four” and thus is overdue for significant attention.

.