What is a Machinery Lubrication Engineer?

A Machinery Lubrication Engineer (MLE) is a special designation. MLEs are “real-world” lubrication and reliability experts. Their knowledge is not limited to books, scientific research, mathematical models, tribology journals or formulation chemistry. Instead, MLEs are hands-on professionals who practice in their field, who have learned more from experience than theory and who focus more on the practical than the abstract.

Through studying and testing, qualified candidates can earn the right to hold this prestigious title of Machinery Lubrication Engineer (MLE). Unlike other exams and certifications related to lubrication and lubricant analysis, the MLE stands alone as the highest professional designation in our industry. It also has a more holistic purpose.

Those interested in training with Noria to prepare for this certification have the option to train in a virtual classroom with Noria experts or through on-demand recordings. Live, in-person training associated with this certification is held a few times per year as well.

Many know that the International Council for Machinery Lubrication (ICML) was organized to serve practitioners in the lubrication field, especially maintainers of lubricated mechanical machinery. So, it makes sense that the MLE would have a similar focus and purpose.

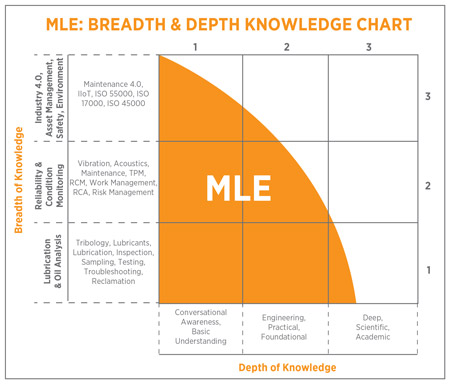

Figure 1. The breadth and depth

of knowledge to become certified as a Machinery Lubrication Engineer.

Responsibilities of a Machinery Lubrication Engineer

An MLE is a professional with extensive training and experience. Certification validates competency, which is why it's common for MLEs to hold other certifications such as Certified Maintenance & Reliability Professional (CMRP), Machine Lubrication Technician (MLT), Machine Lubricant Analyst (MLA), Certified Lubrication Specialist (CLS) or Certified Reliability Engineer (CRE).

Most MLEs will pursue a management path, but others may prefer more technical jobs like staff engineer, consultant or advisor. In a typical plant, the MLE likely will have task responsibility over technicians, analysts, inspectors, operators, millwrights and others performing a wide range of lubrication-related work.

An MLE is a professional with demonstrated competencies in the 24 body of knowledge subject areas. The complete BoK and domain of knowledge can be found at ICML Online.

Skills and Knowledge

Carefully read the MLE responsibilities listed below. The skills and knowledge needed to perform the jobs on the list are extensive and run deep. In an age of Industry 4.0, Maintenance 4.0, lean manufacturing and asset management, it would be foolhardy to view the responsibilities of the MLE as trivial or pedestrian.

The concept and definition of lubrication excellence have been rewritten and will continue to evolve. The bar has been raised and is held as the new standard of excellence. The MLE is a high distinction and is ready today.

Figure 2. The list of 12 ICML 55 subjects along with an illustration showing the stages of maturity for full compliance and certification.

Routine Tasks of a Machinery Lubrication Engineer

The following is a breakdown of the many routine jobs or tasks that may fall under the responsibility of a Machinery Lubrication Engineer. Of course, this will vary considerably from company to company.

Selection of Lubricants

-

Oversees the selection and performance specifications of all lubricants

-

Establishes grease vs. oil guidelines

-

Ensures lubricants are optimally selected with respect to cost, reliability, energy conservation, safety, quality and environmental factors

-

Ensures lubricants are compatible with the machine, process fluids and work environment

-

Writes standards for all lubricant products

-

Implements a lubricant consolidation strategy

-

Is a member of the buying team for selection of lubricant supplier(s)

Selection of Lubrication Equipment

-

Selects oil mist, single-point, centralized and other automatic lubrication equipment

-

Selects oil level control devices

-

Selects sight glasses and bottom sediment and water (BS&W) bowls

-

Selects top-up and dispensing containers as well as fill port hardware

-

Selects lubricant dispensing equipment

-

Selects grease fittings, tags and grease guns

-

Selects storage room tools and equipment

Selection of Contamination Control Products

-

Defines fluid cleanliness and dryness targets

-

Selects filter suppliers, filter types and performance specifications

-

Verifies that lubricants and additives are compatible with filters and separators

-

Selects breathers and headspace-management equipment

-

Selects oil reclamation equipment and/or service providers

-

Selects filter carts and offline filtration equipment

-

Selects lubricant heaters and coolers

-

Selects sump reservoir flushing and cleaning equipment and/or service providers

Management of Lubrication Suppliers and Service Providers

-

Oversees quality, service and support by vendors for lubricants and related products and services

-

Identifies procedures for receiving inspection of incoming products (including lubricants)

-

Establishes lubrication and contamination control guidelines associated with equipment rebuilders

-

Sets up a supplier performance tracking program

-

Routinely communicates supplier performance to purchasing, engineering and management

Lubrication and Inspection PMs and Work Order Management

-

Oversees the writing and scheduling of routine lubrication and inspection PMs, and ensures they are consistent with best practice

-

Oversees staffing and performance of lubrication work orders

Writes Lubrication Procedures to Be Consistent with Best Practice

-

Tank/sump flushing and cleaning

-

Oil drain interval and criteria (interval based or condition based)

-

Top-up procedures

-

Grease gun calibration

-

Handling and storage practices

-

Contamination control

-

Filter changes and used filter inspection

-

Grease gun operation (including how much and how often)

Lubricant Handling, Storage, Consumption and Conservation

-

Oversees all lubricant storage room activities and equipment, including layout, lube container selection, transfer equipment, pumps and tools, ventilation, funnels and hoses, safety equipment and procedures, housekeeping standards, training, record-keeping, etc.

-

Responsible for management of lubricant inventories, reorder points, stock rotation, setting of expiration dates, product labeling and incoming delivery inspections

-

Responsible for tracking and management of lubricant consumption, including leakage control

-

Establishes lubricant consumption strategies

-

Responsible for environmental conservation practices, including best practices for waste oil and used-filter disposal

Develops Lubrication-related Engineering Specifications for New Machinery

-

Identification of all lubrication points, lubricant type, procedure and frequency of relubrication

-

Installation of sampling ports and procedure

-

Set up of oil analysis testing requirements by machine

-

Filter, breather and vent selection

-

Selection of level gauges, sight glasses and other inspection windows

-

Flushing ports and quick-connect selection

-

Initial cleanliness/dryness targets

-

Training of lubrication technicians on proper PMs and inspections

-

Participates in the commissioning of new equipment

Warranty and Regulatory Compliance Management

-

Ensures machines are lubricated in accordance with manufacturer warranties

-

Ensures warranty claims are submitted for defective lubricants and lubrication equipment

-

Ensures all lubricants and lubrication practices (including storage, containment and disposal) are in compliance with relevant government regulations and industry standards

Manpower Planning, Administration, Staff Training and Certification

-

Writes job descriptions, defines job skills and defines certification requirements for maintenance employees/contractors with lubrication responsibilities

-

Manages all lubrication and oil analysis direct-line reports and job responsibilities

-

Conducts quarterly skill-development workshops for lubrication technicians and analysts

-

Selects and schedules onsite training programs, including certification relating to oil analysis, failure analysis, troubleshooting, lubrication best practices and contamination control

Lubrication Information Management

-

Supports the selection and management of lubrication software and other information technology products/processes, including data entry, oil analysis software, predictive maintenance (PdM) software, lubrication scheduling software and related computerized maintenance management system (CMMS) modules

Oil Analysis Program Design and Coordination

-

Selects the oil analysis laboratory

-

Selects onsite oil analysis instruments

-

Selects oil analysis software and report format

-

Identifies when, how and where samples will be obtained

-

Selects routine oil analysis test slate for each machine

-

Sets oil analysis alarms and condemning limits

-

Defines additive reconstruction strategies

-

Performs/coordinates laboratory-quality assurance tests

-

Provides data integration and interface to other reliability technology activities, including vibration, acoustics and thermography

Failure Modes and Effects Analysis (FMEA); Failure Reporting, Analysis and Corrective Action System (FRACAS); Root Cause Analysis (RCA); and Troubleshooting

-

Participates in FMEA and reliability-centered maintenance (RCM) planning initiatives

-

Participates in RCA and FRACAS activities relating to failures of grease- or oil-lubricated machinery

-

Develops troubleshooting templates and fault trees for common machine conditions and trains maintenance staff on their use

Management Reporting and Performance Metrics

-

Defines overall lubrication program goals, budgets and plans

-

Evaluates proposed lubrication capital expenditures using standard economic analysis methods

-

Coordinates annual lubrication audits and benchmarking services

-

Implements overall lubrication effectiveness metrics and other key performance indicators

-

Makes routine progress reports to management and maintenance staff

-

Ensures the overall lubrication activity program is aligned with asset management, reliability, safety and environmental objectives