Best Practices for Controlling Varnish in Hydraulic Systems

Tags: varnish, contamination control, hydraulics, industrial lubricants, oil analysis

Resin-like or solid coating deposits that form in a fluid system are often referred to as varnish. The cause of these varnish deposits is related to oil aging or oil degradation, which can be determined by lab testing the oil. Reducing varnish in a hydraulic system is accomplished with oil care measures, including dewatering and degassing the fluid and avoiding electrostatic discharge and elevated oil temperatures.

To care for hydraulic systems appropriately, it’s important to know:

- Why varnish builds up.

- How to determine if varnish is the primary issue in a system.

- How to select varnish-resistant lubricants.

- Current strategies to remove and reduce varnish deposits.

- Field applications for varnish removal systems.

The condition of oil in lubrication and hydraulic systems indicates the health of the entire system. For ensuring productivity, avoiding malfunctions, and reducing operating costs, it is essential to perform:

- Fluid condition monitoring.

- Timely maintenance for lubrication and contamination control.

What Is Varnish?

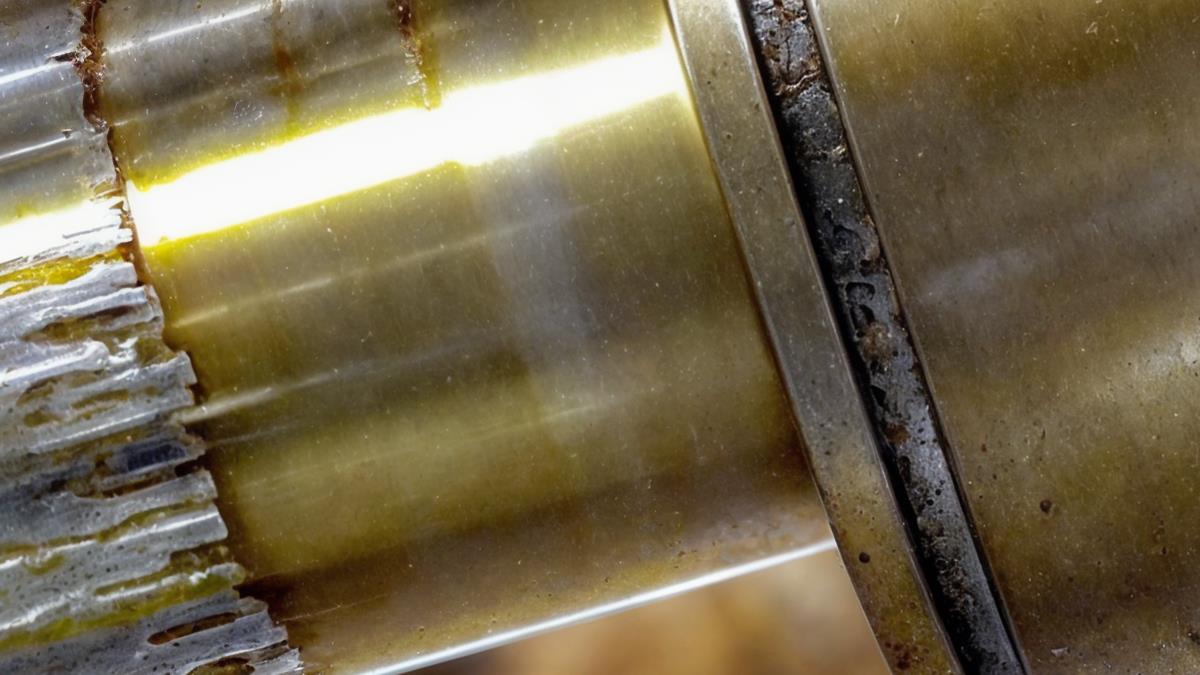

In the context of lubricating and hydraulic systems, varnish refers to resin-like or solid varnish-like deposits that form in fluid systems.

Varnish causes:

- Elevated temperature in turbine bearings due to increased friction in the bearing.

- Operational control problems with the control valve due to increasing deposits in the gap between the piston and the housing.

- Cooling problems because the varnish impedes the heat transfer.

- Shorter filter change intervals.

The cause of these lacquer-like varnish deposits is oil aging. However, in most cases, the above malfunctions are not correctly attributed to the real cause. This results in ineffective and often very expensive repair work.

Causes of Increasing Varnish Formation

Today, system operators are confronted with the fact that the production of the base oils used is changing or has already been changed. Previously, oil was produced exclusively in crude oil distillation (Group I oils). Now, processes reduce the content of substances hazardous to health (e.g., aromatics). The change in the oil production process has resulted in base oils with a lower content of unsaturated/polar hydrocarbons (Groups II, II+, and III). With Group I base oils being polar, polar substances were more easily dissolved.

The changes in oil production have led to oil with less polarity; therefore, there is a reduction in the amount of polar substances being dissolved in a hydraulic system’s oil. Varnish is a polar substance that no longer easily dissolves in newer base stocks.

Polar substances tend to dissolve more readily in other polar substances. If the proportion of polar hydrocarbons in the oil is reduced, oil degradation products – often includes varnish – cannot dissolve as easily. This trend has made varnish formation a more common issue across modern hydraulic systems—unless a lubricant has been specifically formulated to mitigate it.

The Effects of Increasing Varnish

Varnish may seem minor at first, but even small deposits can restrict fluid flow, increase friction, and cause valves to stick or respond sluggishly. The result is higher operating pressures, longer cycle times, and ultimately, greater energy consumption.

Beyond efficiency loss, varnish also accelerates component wear, elevates fluid temperatures, and contributes to more frequent maintenance interventions. Adding to the challenge, many of today’s highly refined base oils—while cleaner and more oxidation-resistant—tend to have lower electrical conductivity. This can lead to electrostatic discharge (ESD) as the oil flows through filters, causing microscopic damage to filters, valves, and other precision components.

Given these operating realities, lubricant formulation and proactive conditioning have become critical drivers of long-term efficiency and cost control.

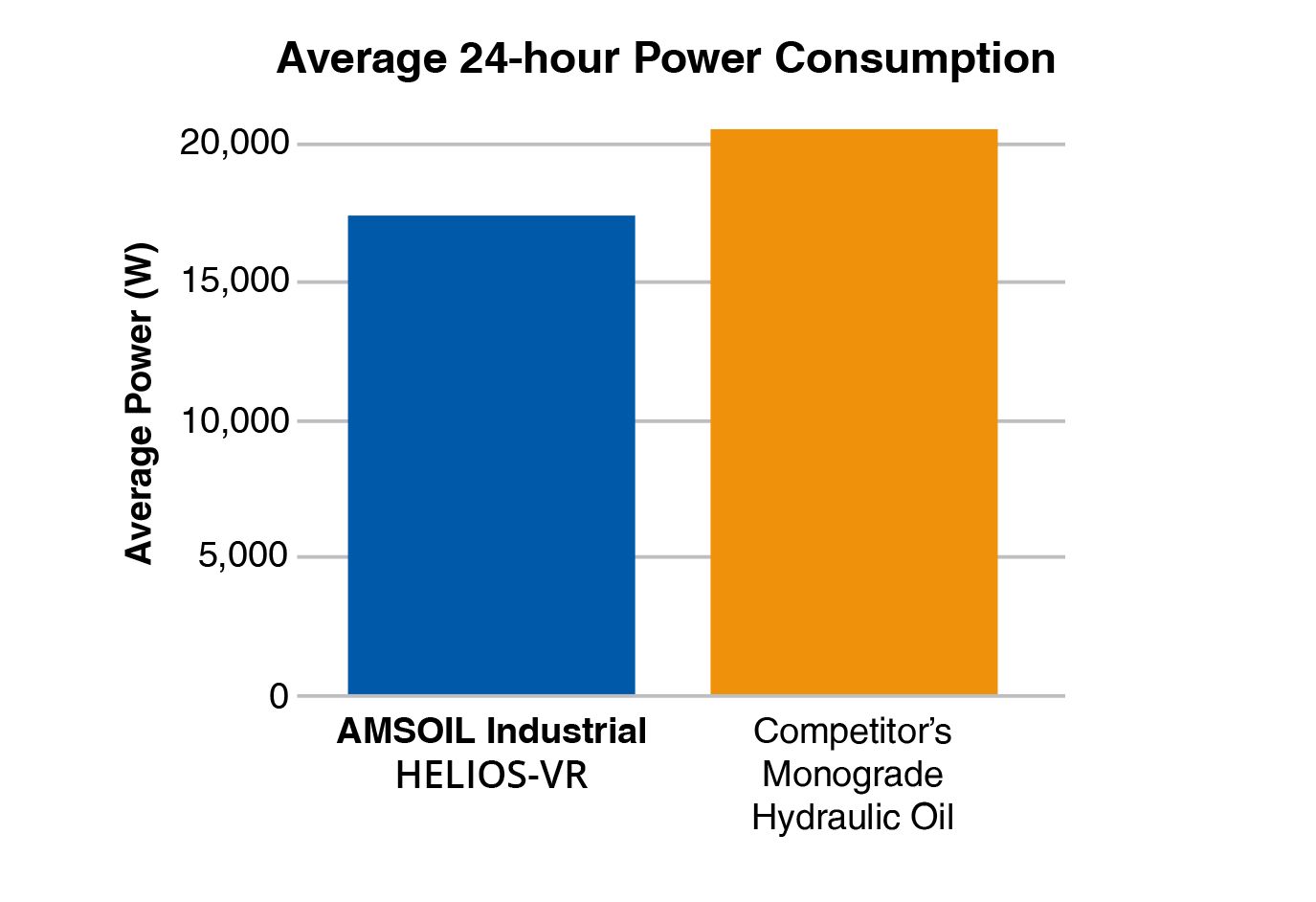

Proven Impact: In a continuous 24-hour production test, average power consumption with a conventional monograde hydraulic oil measured 20,189 watts. When replaced with AMSOIL Industrial HELIOS-VR™ Synthetic Varnish-Resistant Hydraulic Oil, power usage dropped to 17,415 watts—a difference of 2.77 kW, or 13.7% less energy consumed under identical operating conditions.

How to Recognize Varnish

Varnish in oil cannot be detected through routine lab analysis. Instead, labs utilize Membrane Patch Colorimetry (MPC) testing. Varnish can be seen as a dark precipitate on a filter membrane, and MPC tests record these changes in color on filter membranes with a 0.45µm filtration rating. Critical system conditions occur if the MPC value is over 40.

Laboratory particle counting will differ significantly from online measurements that use a portable particle counter; for example, a laboratory measurement may give 24/23/17 while an online measurement will be 16/14/10. This is because the solubility of the varnish in the oil depends highly on temperature.

When the oil sample is cooled down, the solubility limit in the oil is exceeded. This is mainly counted in the ISO code's 4- and 6-micron ranges, resulting in a significant difference compared to the 14-micron code. Usually, there is a difference of up to 4 codes between 6 and 14 microns. As soon as varnish is present, this difference can be more than five codes in the laboratory particle count at room temperature. This exceedance of the solubility limit is reversible; when the temperature increases, the varnish goes back into the solution.

How to Reduce Varnish Formation

An oil’s degradation rate can be reduced with oil care measures. These include:

- Offline Filtration: Limits the growth in particle size.

- Dewatering: Minimizes additive reduction due to leaching.

- Degassing: Reduces contact with air and, therefore, with oxygen.

- Avoid electrostatic discharge in the oil and avoid premature degradation due to local temperature spikes and hot spots.

- Monitor the oil temperature balance to detect elevated friction in the bearing or cooler overgrowth early on.

- Regular oil analyses and trend the remaining useful life (RUL) help to avoid critical system states such as jammed control valves for the steam control of a turbine and unsafe machine operation.

Just as important, selecting a lubricant designed to resist varnish formation from the start can significantly extend oil life, improve system efficiency, and reduce the total cost of ownership.

Advanced Solutions for Varnish Control

While maintenance practices play a major role in minimizing varnish formation, the foundation of a clean, efficient hydraulic system begins with the right lubricant. AMSOIL Industrial has developed two varnish-resistant hydraulic fluids—HELIOS-VR™ Synthetic Varnish-Resistant Hydraulic Oil and PETRAULIC-VR™ Varnish-Resistant Hydraulic Oil—each formulated to address the modern challenges created by changes in base oil chemistry and tighter system tolerances.

AMSOIL Industrial HELIOS-VR™ Synthetic Varnish-Resistant Hydraulic Oil

Built on a synthetic base stock, HELIOS-VRTM delivers exceptional thermal stability and oxidation resistance under severe operating conditions. Its advanced additive system actively resists varnish formation by keeping degradation by-products suspended, preventing deposits from forming on critical surfaces. HELIOS-VRTM helps maintain system responsiveness and cleanliness while reducing friction and energy consumption.

Real-World Performance: Metal Stamping Operation

A Midwest automotive metal-stamping plant, operating multiple large hydraulic presses, was experiencing frequent downtime due to damaged hydraulic control and safety valves. Excessive varnish and sludge accumulation in the existing oil led to short service life, monthly filter replacements, and rising maintenance costs.

Following an on-site analysis, AMSOIL Industrial Application Engineers recommended flushing the system, installing HELIOS-VRTM, and implementing routine oil analysis to monitor varnish potential.

Results: Over an eight-year period, the hydraulic systems remained clean and free of varnish or sludge. The operation achieved:

-

12× reduction in filter replacements (from monthly to annually)

-

Zero oil changes after eight years in service

-

Zero valve replacements required

These improvements translated to approximately $337,500 in annual savings, totaling over $2.7 million in reduced downtime and maintenance costs across eight years—all while maintaining reliable, energy-efficient press performance.

AMSOIL Industrial PETRAULIC-VR™ Varnish-Resistant Hydraulic Oil

For operations that prefer or require a mineral-based formulation, PETRAULIC-VRTM provides similar varnish-resistant performance. Formulated with highly refined Group II base oils and a proprietary additive package, PETRAULIC-VRTMoffers strong oxidation control and deposit resistance while delivering reliable protection and long service life. It’s a versatile option for industrial hydraulic systems seeking to improve efficiency, extend maintenance intervals, and reduce unplanned downtime.

Both HELIOS-VRTM and PETRAULIC-VRTM are engineered to help operators lower total cost of ownership by improving reliability, reducing energy draw, and maintaining clean, efficient hydraulic performance—no matter the application or operating environment.

Systems Used to Reduce the Effects of Varnish

The removal of varnish from system components is a relatively slow process. Oil degradation products are initially individual particles less than 0.1 microns in size. As a result, they can pass through the filter initially without impairing the valve function. During further oil aging or when the oil is cooled down (e.g., during a system shutdown), these particles agglomerate, become larger, and block the valve function and the filter medium.

It is recommended that varnish removal systems (usually affixed as offline filtration skids) are operated over a long period of time or installed permanently. The system varnish removal process can be sensitive to elevated moisture levels in the fluid and the presence of high levels of metal wear particles.

Several technologies and methods can be employed in a hydraulic system to reduce or remove varnish, including:

- Fine filtration

- Electrostatic purification

- Adsorption by disposable media

- Chemical rinsing or flushing of equipment

The functional principle of offline filtration is that polymerized varnish in the range of 2 microns is removed using very fine filtration. An offline filtration system is installed on the hydraulic reservoir for continuous filtration. Cooling the oil with a cooler or chiller prior to a filtration unit allows the varnish precursors to form and be filtered out. The fine filtration will remove the free varnish and is often combined with a purifier or water removal unit.

ESD filter media was introduced to eliminate potential electrostatic charging problems with hydrocarbon fluid filtration. Extensive testing in controlled laboratory conditions and on operating equipment in industrial applications has shown this filtration media significantly reduces damage and the electrostatic charge generation compared to a typical glass-fiber filtration medium. Filter elements are made using a special mesh pack structure to reduce fluid electrostatic charge and are deployed in filter housings.

The use of offline filtration and ESD filter media can result in higher operational safety since sparking, oil degradation, and sludge formation are eliminated. Longer oil service intervals resulting from fine oil filtration can lead to significant cost savings through fewer oil changes, filter element changes, and system breakdowns.

Varnish mitigation units are designed to remove the soft contamination both in suspension and solution. They have a simple design that is easy to use in a wide fluid temperature range. The functional principle of the varnish mitigation unit is to accumulate particles in the range of < 1 micron on the active surface of an ion exchanger.

Accumulating very fine particles improves the solubility of varnish in the oil; the oil becomes "varnish-hungry," and soft oil degradation products already deposited on the surfaces in the system are dissolved back into the oil. The varnish mitigation units don't impact the removal of any hardened oil aging contaminates that have formed on the surface. The advantage of a varnish mitigation unit is that the structure of the ion exchanger provides a large separating surface while reducing the system's operating costs.

The chemical cleaning/flushing method removes varnish by utilizing cleaning chemicals circulated through the system to dislodge varnish from components. The chemicals are added to the hydraulic oil to soften and dissolve the insoluble materials. Then the flushing action suspends the hard deposits in the fluid, which are removed when the fluid is drained. This process is usually performed for several hours or days, depending on the system size and the extent of the varnish build-up. Finally, the system must be flushed with clean oil to remove any traces of the chemicals and then refilled with new oil before use.

Conclusion

Varnish formation has become a growing concern in modern hydraulic systems, largely due to changes in base oil refining. As oils have become more highly refined and less polar, their ability to keep degradation by-products dissolved has diminished. This makes it easier for varnish to form and settle on critical component surfaces.

Proactive oil care practices such as fine filtration, dewatering, air removal, and degassing can slow varnish formation and extend oil life. However, long-term prevention begins with the lubricant itself. Selecting a hydraulic oil formulated to resist varnish formation helps maintain system cleanliness, improve energy efficiency, and reduce maintenance costs.