Just as we take care in selecting turbine oils for specific applications and purposes based on their properties, it takes a similar amount of focus and attention to ensure that these important lubricants are kept clean and protected both before they are put into service and throughout their service life. This includes the shipment, reception and storage of “new” turbine oil as well as oil that is in service or nearing the end of its service life.

In this paper, we will examine important attributes of turbine oils and their additives before moving on to cover varnish formation, detection, and removal methods. Finally, we will discuss practical tips and advice for keeping varnish and other contamination-related problems under control through efficient preventive and proactive maintenance actions.

Topics Covered in This Whitepaper

- Attributes of Turbine Oil

- Base Oils

- Additive Packages

- Water in Oil

- Selecting a Turbine Oil

- Reclamation and Refortification

- Varnish

- Oxidation

- Aeration

- Microdieseling

- Oxidative Oil Degradation

- Thermal Degradation

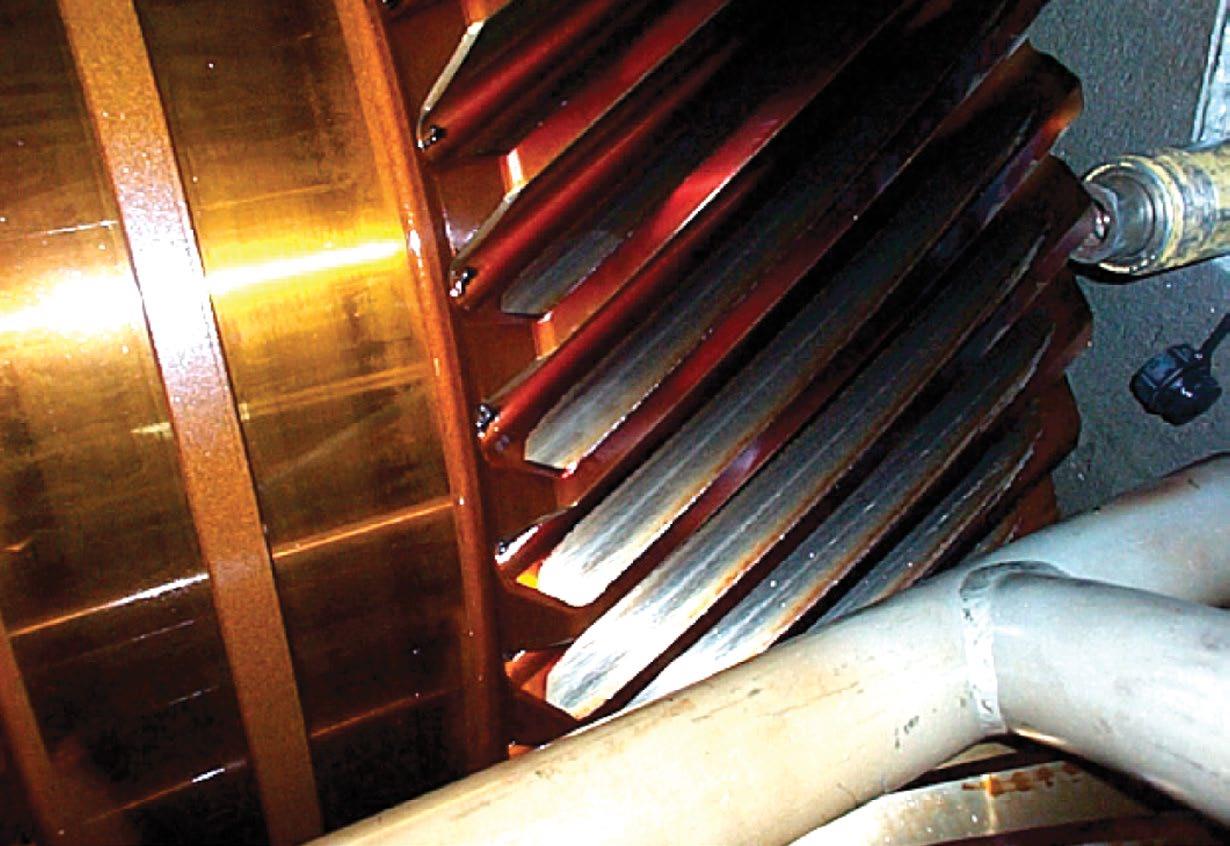

- Impaired Heat Transfer

- Slowed Oil Supply

- Cavitation

- Electrostatic Discharge

- Analysis Techniques for Monitoring Sludge and Varnish

- Preventive and Proactive Solutions for Varnish Problems

- System Cleaning

- Cleanliness

- Filtration, Headspace Control, Storage, and Handling

Thank you to Chevron for sponsoring this educational whitepaper. If you'd like any help with turbine oil selection or want to learn more about VARTECH®, a Chevron representative would be happy to assist you.