After several years of working in maintenance, I have found that there’s no replacement for proper machine alignment. In every training course I taught while at Noria, I explained that no lubricant can protect against misalignment. Considering the thousands of machines that fail annually due to improper alignment, it’s imperative to take steps to enhance your reliability and precision maintenance programs.

When performed correctly, alignment can be an essential part of a proactive maintenance plan. The variety of methods and tools available makes it easy to justify investing the time to do the job right. That said, my first alignment experience involved following an old-timer around as he showed me the ropes. After we set the new motor atop our hydraulic press and cleaned the old grease from the grid coupling, he used a small 6-inch ruler—or straightedge—and laid it across the coupling halves. There was some shimming of the motor to get it parallel with the hydraulic pump shaft, but the whole process was “eyeballed.”

What I learned from this experience over time was that the drive end of the motor ran hotter, the grease was almost always hardened or turned to dust, and we frequently had to replace a broken coupling. From this practice, it’s safe to assume we were part of a reactive maintenance culture—and we were. We never questioned why the coupling disintegrated or why the motors kept failing.

Early in my career, I started a job at a new plant. I was pleasantly surprised to encounter a proactive culture and a shared desire to establish a reliable plant. One of the first steps was purchasing a laser alignment tool, but this was only the beginning. Once we received formal training and began performing more machine alignments, we were able to achieve proper alignment more quickly each time. It certainly beat the previous methods of using straightedges and dial indicators. We also saw a reduction in failed bearings and couplings across the plant.

Identifying Misalignment

Proper machine alignment can be summed up in a simple statement: the shafts are aligned in both the horizontal and vertical planes. Misalignment occurs when the shafts are not parallel or have an angular deviation.

- Parallel misalignment means the shaft centerlines are offset from one another.

- Angular misalignment refers to when the shafts run at an angle relative to one another.

Both types of misalignment can occur simultaneously and in both the horizontal and vertical planes.

- Vertical misalignment is typically corrected by adding or removing shims from the motor or machine feet.

- Horizontal misalignment requires lateral movement of the motor or machine until the centerlines align.

Effects of Misalignment

The effects of misalignment can be catastrophic to a machine. Coupling damage is one of the most common symptoms. When a technician separates the coupling halves for inspection, damage to the grid or teeth often results in the need to replace the entire coupling—though this only masks the deeper issue within the machine.

Misalignment also increases friction along bearing surfaces, leading to greater wear, higher energy consumption, and premature machine failure. Seals can be damaged during the process, causing leakage. If the issue is left uncorrected, even the shaft itself may be compromised.

Once components begin to wear, simply replacing them is no longer sufficient. If the root cause—misalignment—is not addressed, the problem will resurface repeatedly. In my opinion, misalignment is often overlooked as a root cause of failure. It’s frequently blamed on faulty seals or poor bearing installation. Only when maintenance professionals receive proper training and fully understand the importance of alignment can the issue be permanently addressed through corrective action.

Detecting Misalignment

There are several technologies that can help detect misalignment. The most popular options include:

Laser Alignment

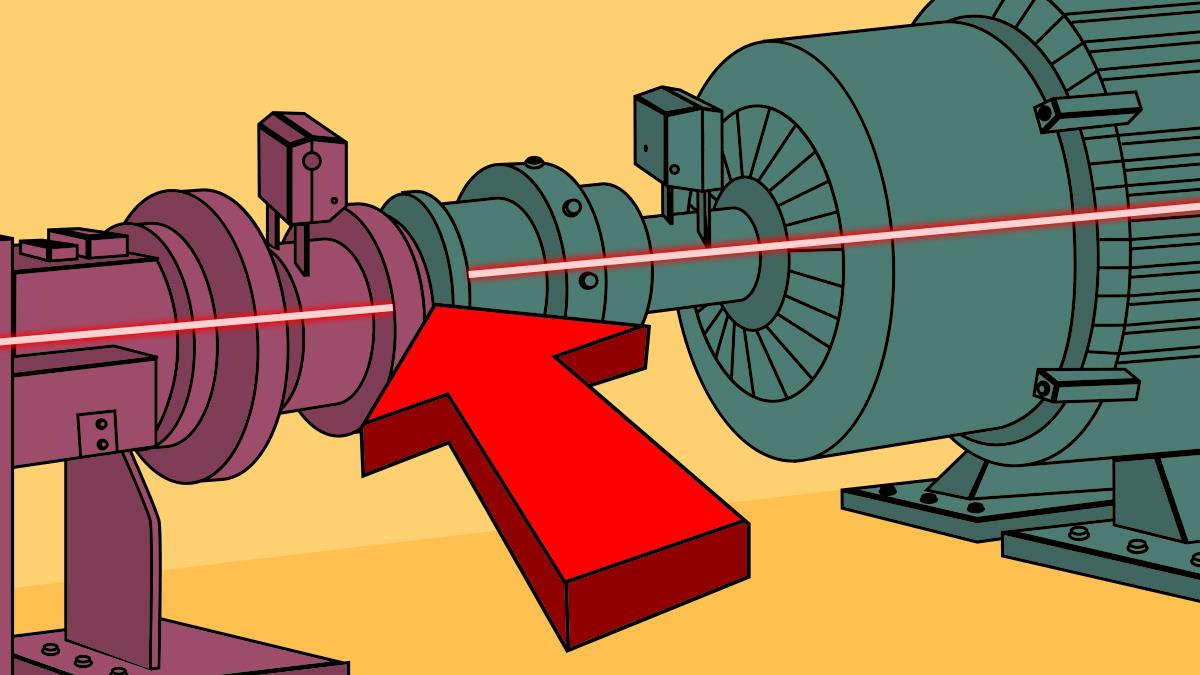

Laser alignment makes it easy to align shafts with precision and accuracy. It works by projecting a laser into a sensor, which then feeds data to a device that calculates the necessary adjustments. Once the laser and sensor are mounted on the driver and driven machines, the shafts are rotated and multiple readings are taken to determine the necessary corrections.

Modern laser alignment tools can also account for the equipment’s metallurgy and offer compensation for thermal growth. Some systems allow for “live alignment,” where the technician performs initial alignment, starts the machine to operating temperature, then shuts it down for final measurements to assess thermal expansion effects.

While laser alignment is highly accurate and beneficial for critical equipment, it requires a shutdown and dedicated maintenance time. For equipment that operates on shorter cycles, alternative detection methods may be more practical.

Vibration Analysis

Vibration analysis can identify misalignment by monitoring deviations from baseline vibration responses. Typical vibration readings for misalignment are observed at 1X (axial vibration) and 2X (radial vibration). However, an abnormal reading doesn’t always indicate misalignment. It’s important to take measurements from both the drive and driven ends and rule out other causes before diagnosing the issue.

In some cases, misalignment may not show up clearly in vibration analysis until significant damage—such as bearing failure—has occurred. This reinforces the importance of performing accurate alignment as a proactive step, not merely relying on screening tools.

Thermography

Thermography detects increased heat generated by friction from misalignment. By capturing a thermal image of bearing housings or motor surfaces, technicians can identify abnormal hot spots.

However, elevated temperature isn’t always indicative of a problem. Technicians must compare readings against similar machines and perform consistent checks to accurately detect misalignment.

Oil Analysis

Oil analysis can also help detect misalignment by evaluating machine condition, lubricant quality, and the presence of wear particles. If done correctly—with samples taken from appropriate locations and with clean hardware—it can detect early signs of wear, sometimes before vibration analysis does.

Elemental analysis can reveal elevated levels of materials like iron, aluminum, copper, lead, and chromium, indicating bearing or component wear. Combining oil analysis with vibration readings improves diagnostic accuracy and helps pinpoint the root cause of wear. Misalignment-related wear often produces particles indicative of two-body abrasion, scuffing, and surface fatigue.

Final Thoughts

When setting up machines and investigating failures, proper alignment is often overlooked. Even with the right tools and training, it takes attention to detail and persistence to get alignment right. Some jobs have taken me just ten minutes to achieve precision alignment, while others required a day or more—especially when motor removal or machining was needed.

The difference between an acceptable alignment and a great alignment lies in personnel and precision. For small, low-cost, or redundant machines, being within a few thousandths of an inch may be sufficient. But for larger, critical machines, your goal should be as close to zero deviation as possible.

Focus on proactive alignment and doing it right the first time. The most effective maintenance programs document their alignment results and use predictive tools to monitor changes over time. By combining alignment technology, condition monitoring, training, and the right personnel, your facility can see a significant reduction in failures caused by misalignment.