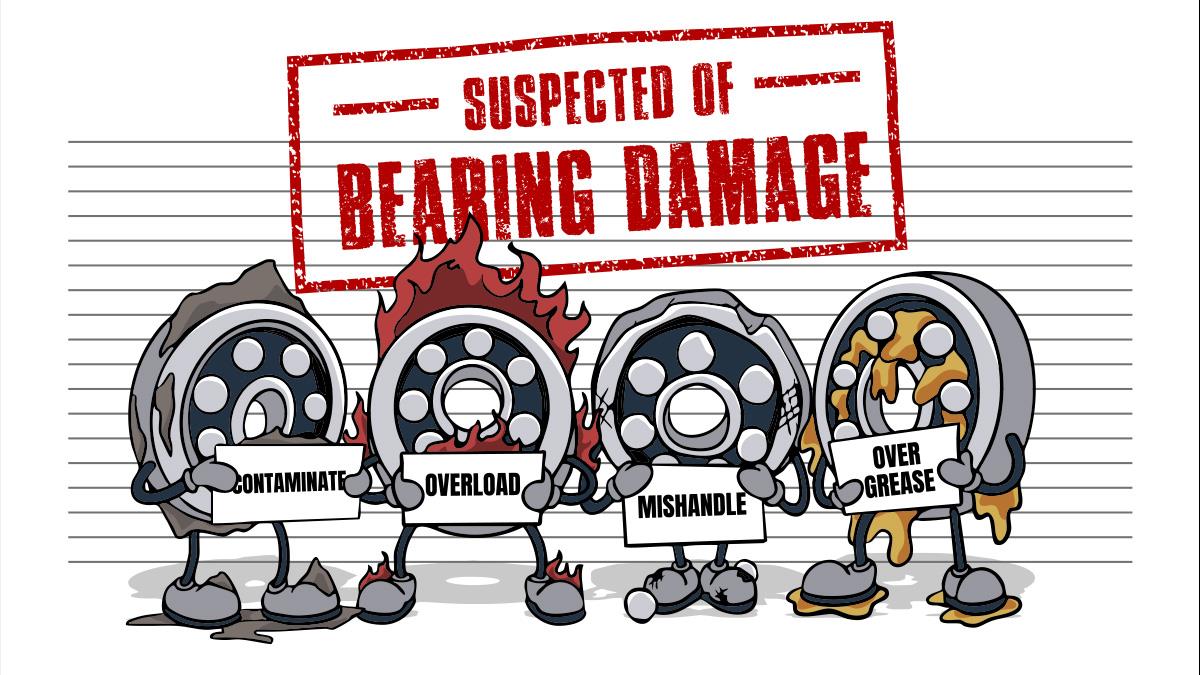

You know the story. The same piece of equipment keeps going down, and it’s always the bearings. You’ve swapped them more times than you can count. You’re starting to feel like you know that bearing housing better than your own living room. And still, the failure shows back up like a bad habit.

At some point, you’ve got to stop replacing and start figuring out why the thing keeps failing.

This is where the rubber meets the road—or more accurately, where the ball meets the raceway—and it’s time for a little good old-fashioned troubleshooting.

First Things First: Get Out of the Break-Fix Cycle

Let’s be real. Most of us in maintenance are under the gun. Production’s breathing down our neck. The last thing anyone wants to hear is, “We need a root cause analysis.” They want the line running. So we slap in a new bearing, hit start, and hope it holds till next shift.

But here’s the truth: if we don’t get ahead of these failures, they’re going to cost us way more than just another bearing. Downtime eats revenue. And repeat failures? They’re a neon sign that something’s wrong upstream.

So if a bearing fails more than once in short order, don’t just change it—investigate it.

Lube It Right—or Don’t Bother

I’ve lost count of how many failures I’ve traced back to bad lubrication practices. Either we’re not giving it enough grease, we’re giving it too much, or we’re using the wrong kind altogether.

Ever seen a bearing cavity packed so tight it looks like a jelly donut exploded in there? That’s not helping. Over-greasing actually creates more heat, not less, and can blow out the seals.

On the flip side, some of our guys treat re-lubrication like flossing—only when reminded by the dentist (or planner). But if the bearing runs dry or the oil’s degraded, you’re just rolling metal on metal.

Then there’s contamination. Water, dirt, coolant mist—any of it can get into the lube and trash your bearing faster than you can say “PM overdue.” If your seals are weak or your breather’s open to the environment, you might as well be inviting the failure in for coffee.

Here’s the bottom line: Clean lube, right amount, right type, applied at the right time. Sounds simple, but it’s usually the first thing we mess up.

Misalignment: The Silent Killer

I used to think alignment was a "when we have time" job. Now I think it should be part of every install, period.

Shaft misalignment puts uneven pressure on the bearing, and you know what happens next—pitting, flaking, overheating, and eventually seizure. I’ve seen new bearings fail in under a week from a lousy install job. One side loads up, the other side floats, and boom—it’s done.

Even if the bearing’s fine, if the coupling’s off or the base is warped, that stress is going to find a way to cause trouble. Use the laser aligner. Dial indicators if that’s what you’ve got. Just do it. “Close enough” isn’t good enough anymore.

Mounting Mistakes and Bad Handling

Bearings aren’t bulletproof. They don’t like being hammered into place with whatever’s handy. A pipe and a sledge? Sure, it’ll go in—but now you’ve brinelled the race and guaranteed a short life.

Use the proper tools. Heat the inner ring if it’s an interference fit. Freeze the shaft if you need to. Don’t spin it dry on install, and for heaven’s sake, keep it clean while you’re working. One speck of grit can become a snowball of destruction inside that housing.

Look at the Load

This one took me longer to learn than I’d like to admit. Bearings are rated for specific loads and speeds. If your machine’s been modified—new motor, heavier throughput, faster speeds—that original bearing spec might not cut it anymore.

Same goes if the equipment is cycling way more often than expected. Every start/stop slams the bearing with force. Over time, it builds up fatigue even if the running load is fine.

Watch for signs like flaking or spalling. That’s the raceway saying “I’ve had enough.” If it looks like someone took a tiny chisel to the surface, you’ve probably got fatigue failure from overload or excessive cycles.

Environmental Nastiness

Bearings don’t like the same things we don’t like—heat, moisture, dirt, and chemical mist. If your machine lives in a hot, wet, or filthy corner of the plant, your bearings are going to suffer.

Sometimes it’s as simple as upgrading the seals. Other times you need to reroute a drain or throw a desiccant breather on a reservoir. But don’t ignore the environment.

I once saw a bearing failing every six weeks until we realized the vent line from a washdown hose was dripping water into the bearing housing. One zip tie later—problem solved. Think like water and grime, and you’ll find the culprits.

What’s Your Maintenance Culture?

If your crew treats every failure like a one-off instead of a symptom, you’ll never get ahead of the curve. And if your maintenance program is all reactive, don’t be surprised when your bearings burn out early.

We started doing condition-based checks—temperature guns, vibration analysis, even just listening with an ultrasonic tool. Sometimes the simplest things can tip you off. Is the housing hotter than normal? Is it noisy? Is there grease seeping out of one side?

You don’t need a million-dollar predictive maintenance program to catch bearing issues early. You just need some discipline and a little curiosity.

Final Thought: It’s Not Just a Bearing

It’s easy to think of a bearing as a ten-dollar part. But when that bearing fails, what’s the actual cost? Downtime, lost production, overtime for the techs, maybe even a ruined gearbox or motor.

A failed bearing is never just a failed bearing. It’s a symptom. Something caused it. If we don’t treat it that way, we’ll be back next week doing the same job all over again.

So next time a bearing comes across your bench, ask yourself:

- Was it lubricated right?

- Was it aligned and mounted right?

- Is the environment working against it?

- Is the load within spec?

- Are we treating maintenance like a process or a panic button?

Fix the answers to those questions, and chances are, you’ll fix the bearing problem too.

Supplier Spotlight

Noria Academy 1328 E. 43rd Court, Tulsa, OK 74105 800-597-5460 | Noria.com/Academy

Obtaining certification can be a challenge; new terms, concepts and topics can overwhelm even the most experienced reliability professionals. Training experts all agree that extending the learning beyond the classroom dramatically increases knowledge retention. To aid in this retention and create an innovative student experience, Noria is pleased to offer the Noria Academy app.

RelaWorks 1328 E. 43rd Court, Tulsa, OK 74145 918-392-5058 | RelaWorks.com

Finding the right products can be difficult. Every industry and application is unique. Over-spending and guess work is common. At RelaWorks, we help reliability professionals solve this challenge. Our mission is to provide products for your unique needs and budget. Backed by Noria Corporation’s expertise and legendary customer service, we’re excited to help your reliability program succeed.

LubePM 1328 E. 43rd Court, Tulsa, OK 74105 800-597-5460 | LubePM.com

As a Lubrication Management System (LMS) engineered by lubrication professionals, LubePM helps an organization create accountability to ensure that every lubrication point is carefully maintained, inspected and measured. Ready to take your facility’s Lubrication Management System to the next level with LubePM? We’re ready to help. Simply request more information or schedule a demo.