Integrally geared centrifugal air compressors are multi-shaft machines used worldwide to provide high volume, high-pressure air for essential plant functions. These compressors use a central bull gear to drive one or more pinion shafts, each equipped with one or two impellers per compression stage. These compressors can span many applications across oil and gas, petrochemical, air separation and other industries.

In an integrally geared centrifugal air compressor, the lubrication requirements must consider both the high-speed rotating elements and the low-speed gear elements. The high-speed pinions can operate at tens of thousands of RPM on hydrodynamic bearings, whereas the bull gear, operating at the motor’s input speed of just a few thousand RPM, must withstand the load transferred from the motor to the pinions. In this case, the lubricant must provide sufficient lubricity to the bearings for smooth operation while also being robust enough to protect the gear mesh between the rotating elements.

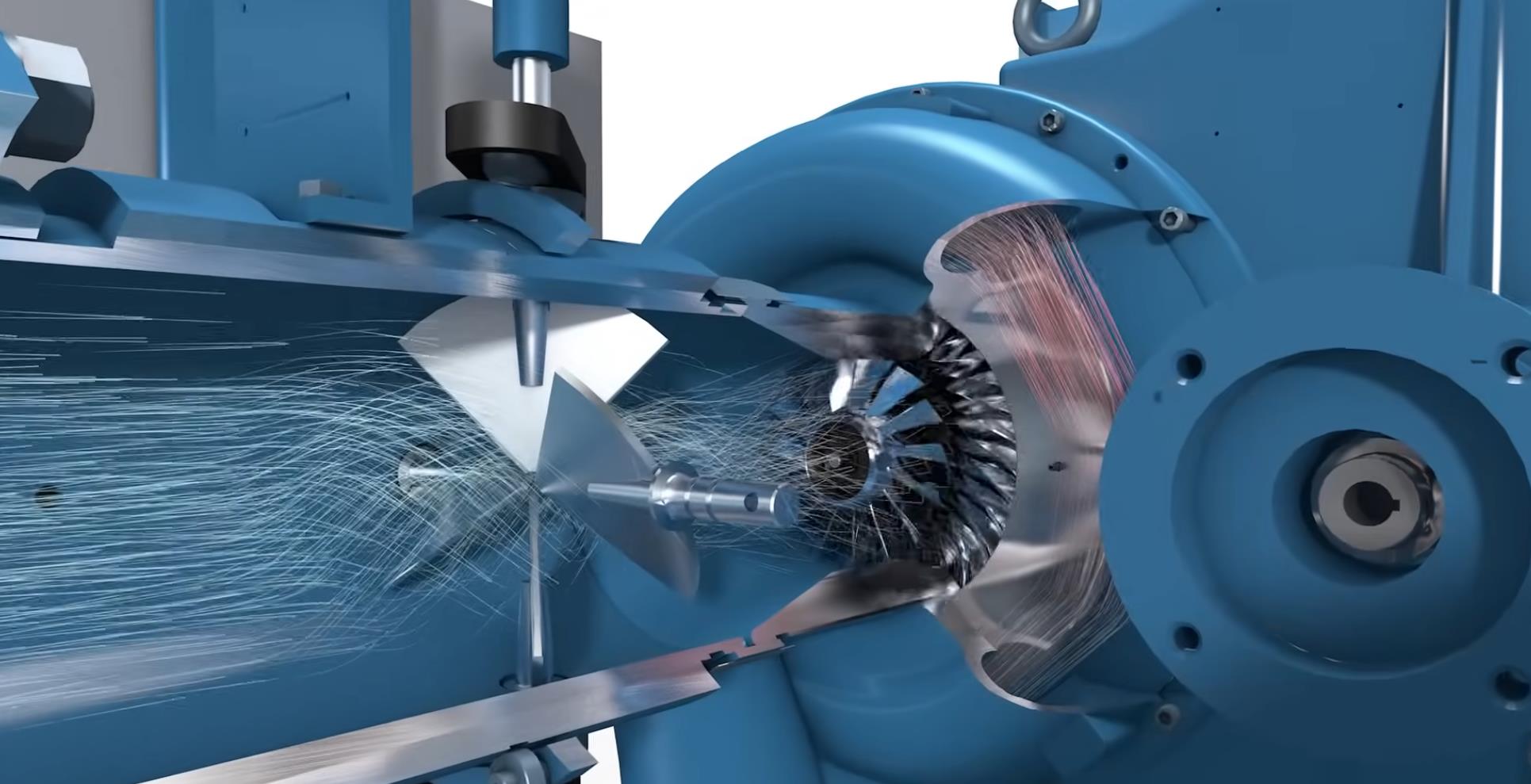

Figure 1. Lubricated Components of an Integrally Geared Air Compressor

When selecting a lubrication solution, you’ll encounter several oil classes, each derived from a specific base oil. These are typically broken down into the base oil groups I through V as defined by API 1509 Appendix E.

Figure 2. API Oil Groups

Refined Hydrocarbons

Lubricants formulated with a Group I refined hydrocarbon base are the most economical option. Basic solvent refined mineral oils generally offer adequate lubrication for integrally geared centrifugal compressors, but they lack the longevity-enhancing properties of more highly refined base oils. In integrally geared centrifugal air compressors, the hottest part of the machine will occur within the high-speed pinion bearings and must be considered when choosing an appropriate lubricant. Lubricants containing Group I bases often must be supplemented with high levels of additives and ester blends to increase their thermal and oxidative suitability.

Group II and Group III oil base oils represent more highly refined mineral oils that have fewer potential impurities and better molecular construction leading to higher thermal and oxidative stability. Group II and Group III base oils are similar but differ primarily in their refining methods: Group II oils are hydrotreated, while Group III oils are hydrocracked. These highly refined mineral oils gained significant popularity over Group I mineral oil as they are far less volatile with fewer impurities, making them a safer choice in many applications.

A key characteristic of Group I through Group III refined hydrocarbon base oils is that their molecules are non-polar, with evenly distributed electrons and no distinct positive or negative ends. Oxidation byproducts typical in high-speed machinery, on the other hand, are polar molecules that like to stick together easily. When these byproducts are produced, if they are not captured and solubilized, they will fall out and deposit on the interior surfaces as varnish. Any lubricant using a refined hydrocarbon base will necessarily rely on the antioxidant additives to bind to the oxidation byproducts and keep them in solution in the lubricant.

A subgroup of the official API Group III designation, some products may be referred to as Group III+. These lubricant bases typically have a remarkably high viscosity index and are used in premium products. Many Group III+ products are derived from alternative refining techniques, such the conversion of natural gas to liquids processes such as the Fischer-Tropsch process. This produces an even more refined hydrocarbon base that relies less on additives to achieve lubrication performance.

You can expect that a high-quality lubricant based on a Group II or Group III base oil whether from the original manufacturer or from a third party should be able to last at least 2 years or 16,000 hours under normal operating conditions.

Full Synthetics

Although Group IV base oils—PAOs (polyalphaolefins)—can deliver performance comparable to advanced Group III hydrocarbon oils, they generally offer no significant advantages and tend to be more expensive. Like the refined hydrocarbons, a PAO based lubricant relies on additives and blending with esters to achieve sufficient lubricity and protective properties required. As such, PAO based lubricants have fallen out of favor with regards to both integrally geared centrifugal air compressors but also other industrial lubrication applications as well. Some manufacturers still offer PAO based compressor lubricants as the “full-synthetic” marketing term can be enticing over refined hydrocarbon-based options, but fewer remain.

The most premium—and markedly different—lubricant for centrifugal air compressors is based on a Group V PAG (polyalkylene glycol) formulation. The further turn in industry toward this synthetic is driven by its polar molecules, having a negatively and a positively charged end. Polyalkylene glycol has near zero varnish potential by itself but when oxidation by-products form threatening sludge or varnish, they are also polar in nature, allowing them to dissolve back into the lubricant and helping to prevent the possibility of deposition and subsequent varnish formation. This natural solvency characteristic leads to an excellent overall resistance to varnish formation as the oxidation particles remain trapped in suspension in the lubricant rather than depositing on system surfaces.

Other common advantages to consider with a PAG based lubricant are greater thermal conductivity, faster air release and higher electrical conductivity.

While a PAG based lubricant may initially cost more than other lubricants, the longevity and resistance to the formation of oxidation make it an excellent choice in many applications. A quality PAG based lubricant under optimal operating conditions can last two to three times longer than a comparable hydrocarbon-based lubricant.

Note that for applying a PAG based lubricant in place of an existing lubricant product, the PAG will have a higher viscosity index than the hydrocarbon equivalent. Because of this you will want to ensure that the viscosity chosen matches your application at the normal operating temperature of the machine as opposed to the ISO viscosity at 40°C. For example, a compressor that specifies the use of an ISO 32 hydrocarbon lubricant may use a PAG based lubricant with an ISO viscosity rating 10% to 20% lower.

Advances in lubrication refining and technology have ushered in a variety of options when it comes to compressor lubrication and across industry in general. Current offerings allow a variety of alternative paths that may allow you to consolidate suppliers, improve your reliability or solve existing problems. While there are various lubricant options available to suit different applications, investing in a high-quality solution is almost always the best choice for long-term performance, reliability, and total cost of ownership. When in doubt, always consult your equipment manufacturer or trusted service representative to ensure the optimal choice for your system.